The grand opening of the Innovation Center was graced by the presence of nearly a hundred distinguished representatives from industry, government, and academia, coming together to witness a major milestone in smart manufacturing.

The grand opening of the Innovation Center was graced by the presence of nearly a hundred distinguished representatives from industry, government, and academia, coming together to witness a major milestone in smart manufacturing.

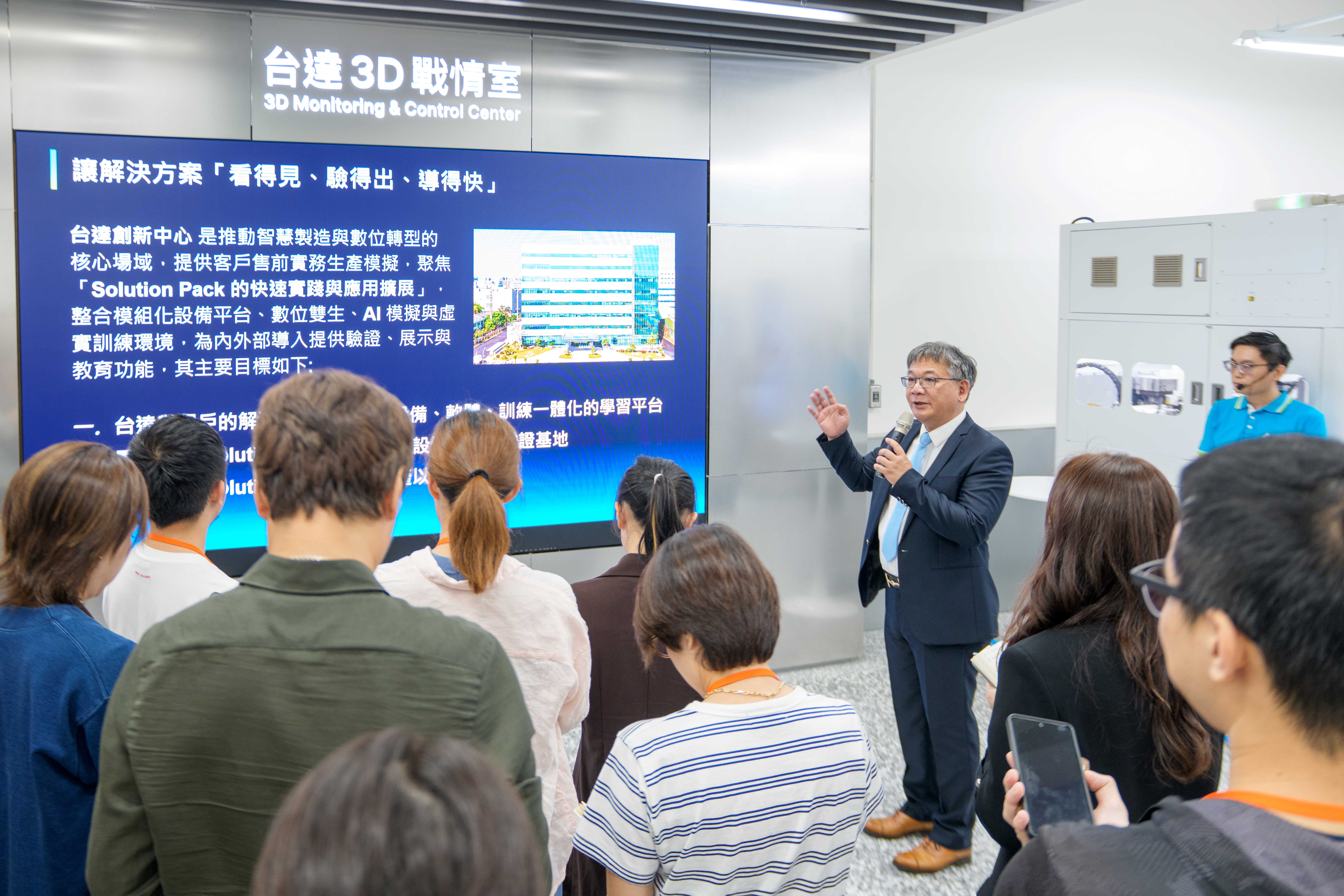

The center showcases comprehensive smart manufacturing solutions—from single machines to full production lines—offering hands-on operation and verification to shorten deployment cycles.

Simon Chang, Delta’s President and COO, remarked, “Delta has long been dedicated to the research and development of smart manufacturing solutions, with AI offering us the opportunity to expand our capabilities in the field. This center represents a significant milestone thereof, and we are honored to deepen our partnership with NVIDIA, working together to implement digital twin applications through NVIDIA Omniverse training resources. In today’s rapidly evolving environment, we aim to leverage our unique experience and expertise to assist partners in the electronics and semiconductor industries in developing high-performance and scalable smart machinery and production line planning solutions that can be quickly replicated in new factories, ultimately shortening product development cycles and speeding up global manufacturing footprints."

During networking, guests from industry, government, and academia engaged in lively discussions, exchanging insights on smart manufacturing trends and exploring opportunities for cross-sector collaboration.

Transformation in Electronics and Semiconductors

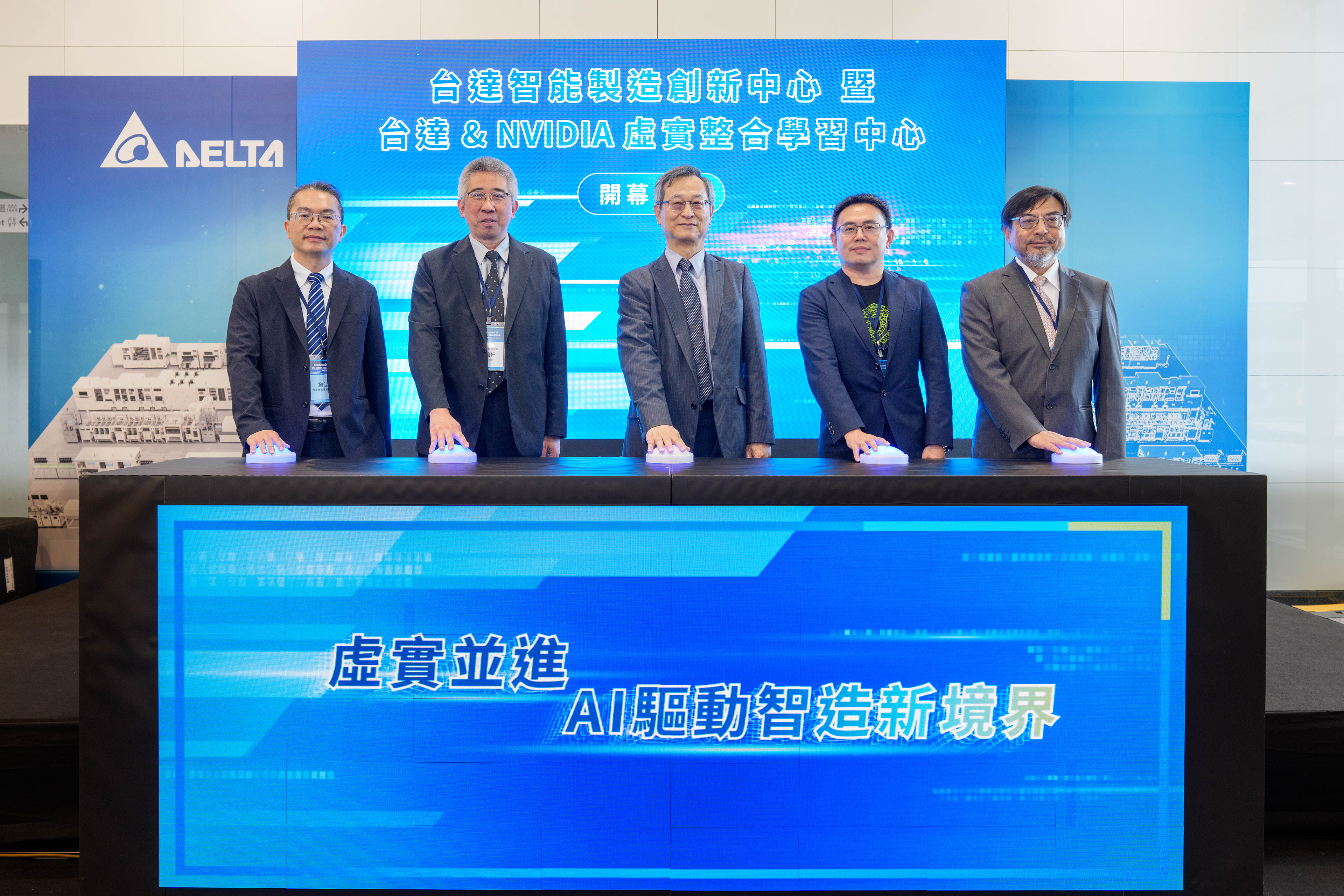

Delta unveiled its Smart Manufacturing Innovation Center—an advanced hub designed to accelerate equipment validation, talent development, and industry upgrades. Addressing global trends in decentralized production and centralized management, the center offers hands-on training, testing, and real-time equipment validation, positioning itself as a one-stop solution for industrial automation. The opening ceremony gathered nearly 100 distinguished guests from industry, government, and academia, including: Mr. Kuo-Hsuan Chen, Secretary General, Industrial Development Administration (IDA), MOEA, Mr. Sterling Lin, Chairman, Taiwan Electronic Equipment Industry Association (TEEIA), Mr. Ethan Hsiao, Head of Enterprise Business, NVIDIA Taiwan. Guests gathered to press the launch button for the Innovation Center. From left to right: Mr. Andy Liu, Delta IABG GM, Mr. Kuo-Hsuan Chen, Secretary General, Industrial Development Administration (IDA), MOEA, Mr. Simon Chang, Delta President & COO, Mr. Sterling Lin, Chairman, Taiwan Electronic Equipment Industry Association (TEEIA), Mr. Ethan Hsiao, Head of Enterprise Business, NVIDIA Taiwan.

Guests gathered to press the launch button for the Innovation Center. From left to right: Mr. Andy Liu, Delta IABG GM, Mr. Kuo-Hsuan Chen, Secretary General, Industrial Development Administration (IDA), MOEA, Mr. Simon Chang, Delta President & COO, Mr. Sterling Lin, Chairman, Taiwan Electronic Equipment Industry Association (TEEIA), Mr. Ethan Hsiao, Head of Enterprise Business, NVIDIA Taiwan.

Accelerating Equipment Validation and Adoption

With a fully equipped environment for trial production, equipment testing, and on-site validation, the center helps electronics and semiconductor clients streamline integration and boost implementation quality. Collaboration with system integrators and end-user engineers ensures that new technologies move smoothly from proof-of-concept to real-world deployment.

Training for Digital Twin and AI Integration

In response to growing demand for AI and digital twin solutions, Delta is introducing hybrid training programs through its DIATwin platform. These programs cover full-line and single-machine integration, production optimization, and smart process management. Featuring scenario-based learning and tiered instruction, the courses aim to build future-ready talent. Looking ahead, it also plans to introduce NVIDIA Omniverse and Isaac Sim training courses, which focus on digital twin technologies and equipment simulation, leading participants to explore the latest trends and practical applications of AI. The Cyber Physical Integration Classroom offers hands-on practice and training, enabling industry talent with AI and digital twin knowledge.

The Cyber Physical Integration Classroom offers hands-on practice and training, enabling industry talent with AI and digital twin knowledge.

The demo production line combines physical equipment with virtual simulation to create a high-fidelity smart factory—enhancing efficiency and accelerating new product introduction.

Delta’s Innovation Center marks a major step in advancing Taiwan’s role in global manufacturing. By fostering industry collaboration and offering scalable digital transformation solutions, it sets a new benchmark for smart, resilient, and future-ready production.