A compass for our journey together

Every day, each of us makes thousands of decisions. Some are small and almost automatic; others carry greater weight and shape outcomes for teams, customers, and the organization as a whole. In a global environment marked by speed, complexity, and constant change, the question is not how many decisions we make, but what guides them.

At Delta, our core values serve as that guide. They function as a shared compass — helping employees navigate choices, align actions, and move in the same direction, even when circumstances differ across roles, regions, and cultures. Integrity, Innovation, Inclusion, Collaboration, and Empowerment are not abstract ideals; they are principles that support consistent, confident decision-making in everyday work.

When values are truly embedded, they reduce ambiguity. They help employees act faster without losing direction, make sound judgments under pressure, and collaborate effectively across boundaries. In this sense, alignment on core values is not only cultural — it is strategic. It enables trust, clarity, and shared ownership in an organization where not every situation can be solved by rules or processes alone.

Starting with a shared experience

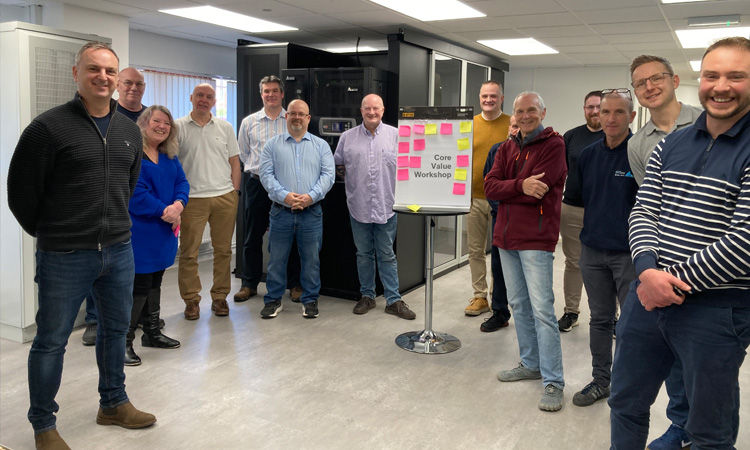

This understanding shaped the launch of Delta’s Core Values Workshops, beginning with a pilot in the Netherlands. The pilot created space for employees to pause, reflect, and reconnect — not only with Delta’s values and mission, but also with one another. Participation reached nearly 94%, and feedback was overwhelmingly positive.

Beyond strengthening understanding of the values, the workshops became an opportunity for teams from different departments to come together, exchange perspectives, and learn from each other. One participant reflected that “Through this training, I gained a deeper understanding of empowerment. In the future, when facing challenges, I will proactively seek resources and feedback from those around me; when encountering setbacks, I will recover more quickly. I am also more willing to share my experiences with colleagues, support and encourage them, helping the entire team succeed—I believe this will be a truly joyful experience.” Others highlighted how the sessions helped bring clarity to everyday work decisions, noting that when challenges arise, “leaning on our five core values helps point us in the right direction.”

Left: Delta EMEA hosts Core Values workshops in the Netherlands, achieving an impressive 94% participation rate.

Right: With nearly 50 workshops conducted, the EMEA program earns a high satisfaction rating of 4.6/5.

From local pilot to regional movement

Encouraged by the strong response, Delta invested in building a network of HR Core Values Ambassadors. These ambassadors were trained to carry the conversations forward, ensuring that the approach remained authentic while adaptable to local contexts.

Through this network, the workshops gradually cascaded across the EMEA region, reaching teams in countries including Turkey, the United Kingdom, Poland, Italy, Spain & Slovakia. In total, nearly 50 groups of employees have taken part in the workshops to date.

Across all locations, the response has been consistently positive, with an average feedback score of 4.6 out of 5. Employees across regions recognized the relevance of the values in their daily work. As one participant in the UK shared, “It was reassuring to see that Delta’s company values reflect my own — and it encouraged me to collaborate more closely with colleagues to achieve our goals.”

Thanks to the dedicated efforts of all EMEA colleagues and the Core Values Ambassadors, Delta was honored in late 2025 with the “Best Brand & Values Initiative for Business Culture” Award in Europe.

Delta honored with "Best Brand & Values Initiative for Business Culture" Award in Europe

A global journey of shared experiences

Since the second half of 2023, Delta teams across all regions have actively launched a wide array of learning and dialogue initiatives — each tailored to local contexts, yet aligned with a unified purpose. Through diverse, grassroots efforts, our core values have been deeply embedded into the daily rhythms of every business unit and geography.

These ongoing transformations are not just activities — they are living proof that when values become a shared compass for every employee, we don’t just align our goals — we amplify our resilience and unlock collective energy.

As more locations join this movement, this growing consensus will guide every Delta colleague worldwide — not just to navigate change, but to lead through it with confidence, purpose, and unity. Together, we are shaping a brighter, more sustainable future.

Left: DGC holds a Management Consensus Camp to integrate core values into leadership practices and define clear behavioral standards.

Right: DIN hosts core value workshop across major sites, using case studies and interactive dialogue to deepen employee alignment.

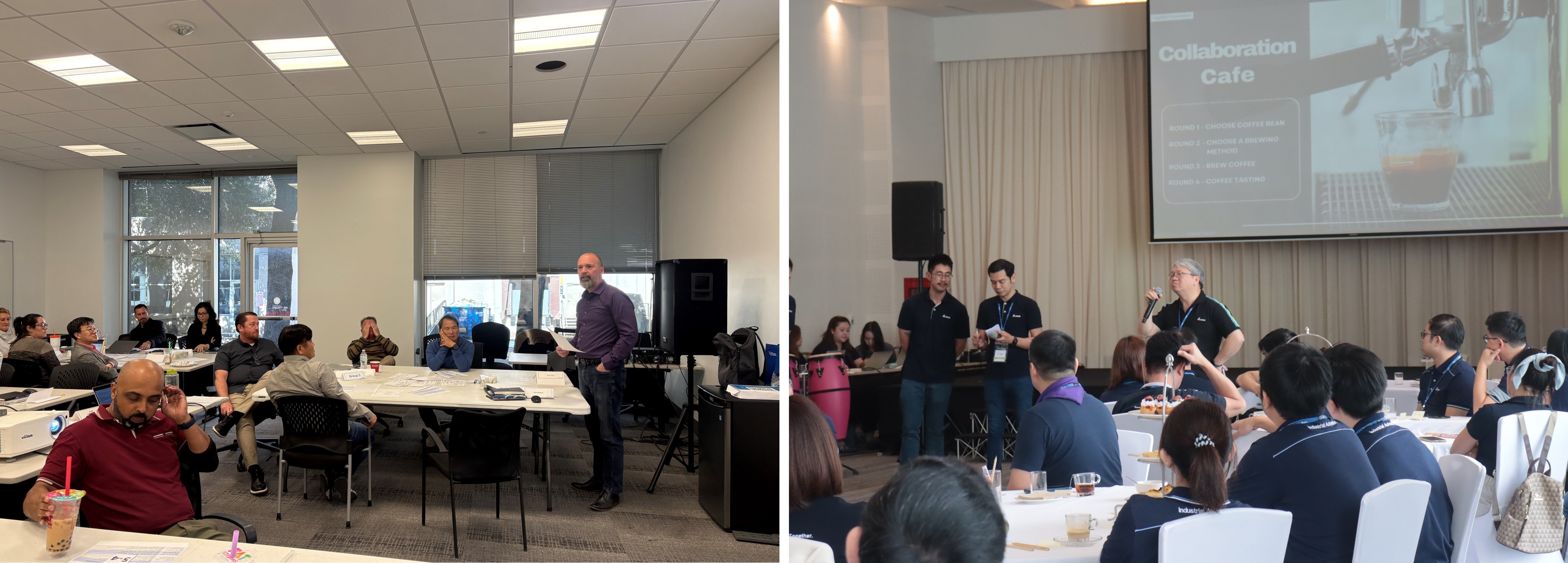

Left: DAL hosts core value workshop in Fremont and Plano, where cross-functional managers engage in group discussions to align on corporate values.

Right: Delta SEA launches the "Collaboration Café" core value workshop in Thailand, featuring leadership experience-sharing sessions to champion core values.

Left: Delta NEA holds core value workshop in Japan, utilizing interactive discussions to strengthen mutual understanding and consensus.

Right: Delta Taiwan hosts over 30 "World Café" core value workshops to deepen employee engagement with our core values.