Delta recently introduced a smart energy saving solution for a food manufacturer in China. The client features an automated quick-freezing production line and high standard plants. However, there is only one general power meter and a few 2nd level power meters, making it difficult to perform a detailed analysis of the electricity bills. In the beginning, Delta installed its Multifunction Power Meter DPM Series to monitor the energy consumption data of the equipment in real-time and set up a complete energy management system. It transmitted the collected data to the DIAEnergie Industrial Energy Management System via the PLC and Ethernet for auto recording, and uploaded to the DIAView SCADA System for visualized analysis. The analyzed data can be further used as a basis of an energy saving strategy.

Delta’s smart energy saving solution for food manufacturing integrates the equipment, controller and communications in the factory for a complete system. The visualized data analysis offers managers equipment operation and energy consumption information in real-time, ensures operation stability, and system safety. The analyzed data can be used as reference for an energy usage strategy that saves production costs.

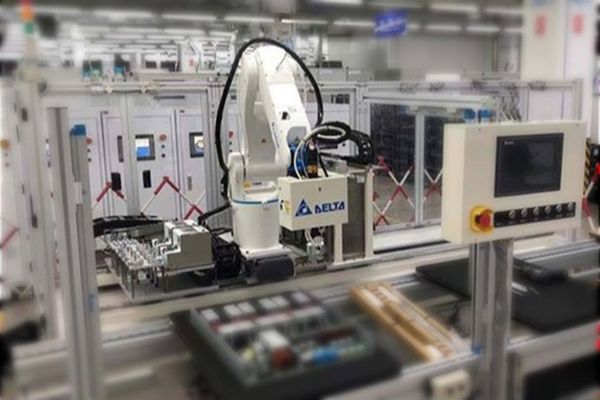

Delta recently implemented a smart energy saving solution for a food manufacturer in China

Delta recently implemented a smart energy saving solution for a food manufacturer in China