Delta recently introduced its articulated robots and machine vision systems to a PCB plant in China for multilayer PCB screw locking. The multilayer PCB production requires labor-intensive screw locking to inspection, taking long working hours and resulting in low quality with frequent errors. Delta implemented its Articulated Robot DRV90L to the production for screw locking. The dual screw locking workstation features manual and robotic work, lowering the error rate. It enhances the workflow and improves PCB manufacturing productivity.

Delta’s Articulated Robot DRV90L can be combined with multiple feeding units, quick changing units for lenses, and a servo screwdriver for real-time torque monitoring. During the process, the feeding units automatically elevate and feed the materials. The Machine Vision System DMV2000 Series identifies materials and screw locking points with auto calibration, then transmits the info to the Compact Modular Mid-range PLC AS Series for quick positioning. The AS Series commands the Articulated Robot DRV90L to execute stable and quick pick-and-place and screw locking.

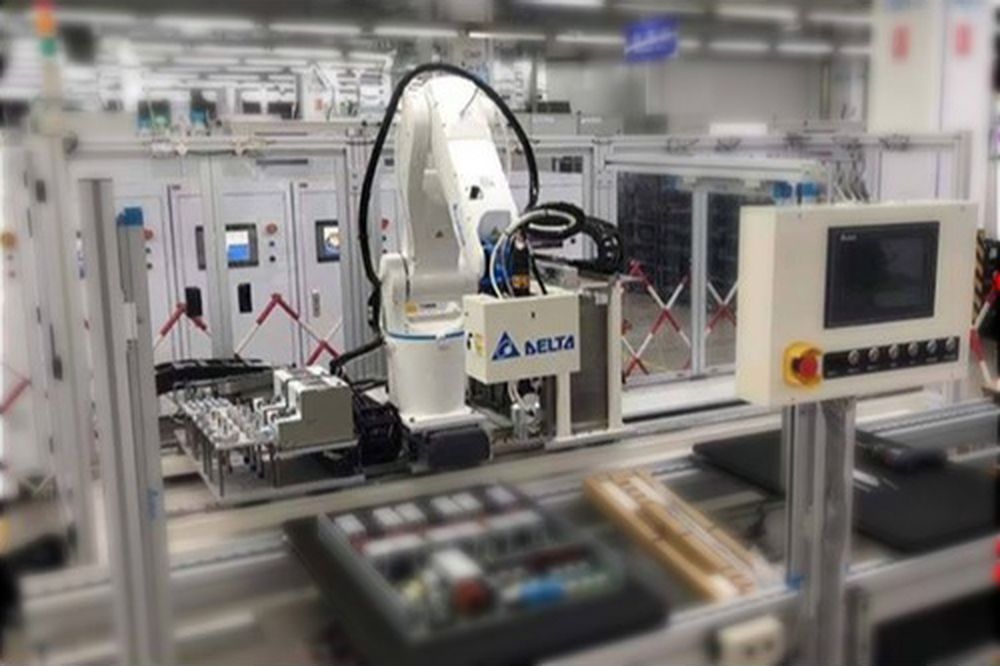

Delta implemented the Articulated Robot DRV90L and a machine vision system to the production line of multilayer PCBs for precise and high-speed screw locking

Delta implemented the Articulated Robot DRV90L and a machine vision system to the production line of multilayer PCBs for precise and high-speed screw locking