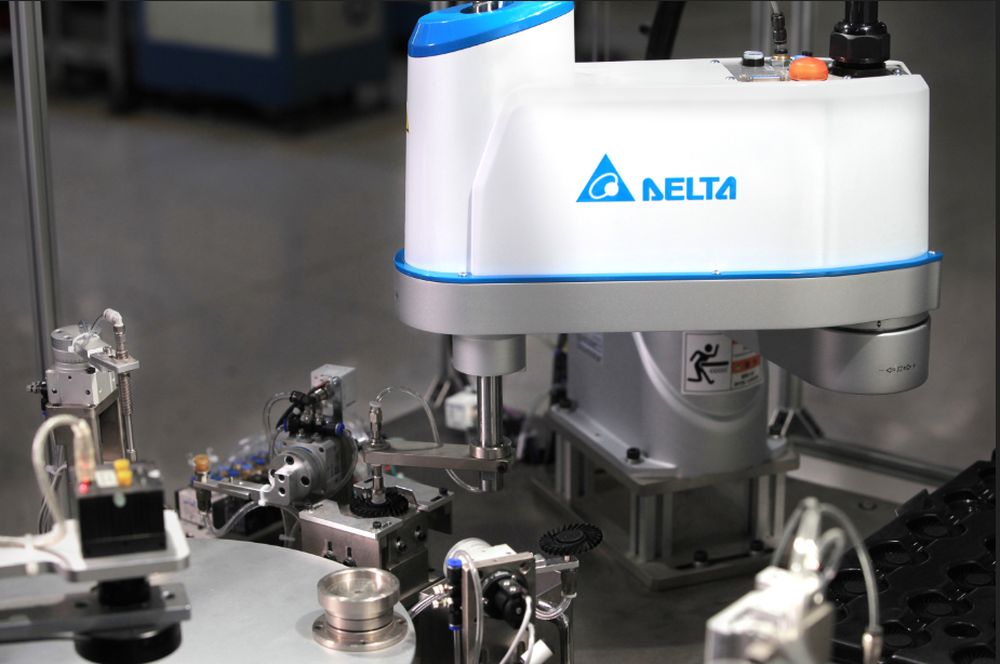

Delta has recently integrated its machine vision system with automated industrial robots on its own production lines in Wujang, China, to inspect the welding of laptop cooling fans. The automated inspection solution implements fast welding inspection during cooling fan production and ensures fan quality.Delta adopts the Machine Vision System DMV2000 Series and two Selective Compliance Assembly Robot Arms (SCARA) for high-performance inspection. The DMV2000 Series accurately positions the iron cases on a tray, and the robot controller DCS Series drives one SCARA robot DRS60L to load iron cases of laptop fans with vacuum suckers and unload them onto the welding inspection machine.

Delta’s automated inspection solutions ensure rapid workpiece positioning with the machine vision system, improve efficiency for welding inspection of laptop cooling fan shafts and iron cases, and enhance fan quality. The solutions are suitable for various applications and for workpieces or products without angle variation such as screw holes.

Delta recently implemented welding inspection of laptop cooling fans on its own production lines in Wujang, China

Delta recently implemented welding inspection of laptop cooling fans on its own production lines in Wujang, China