Blow molding machines are common in plastic container production. A conventional blow molding machine usually operates with hydraulic pressure. It cannot produce precise wall thickness and consumes much energy. In addition, it fails to inject plastic consistently into clamp molds with a stable force, which results in an uneven wall thickness of a container.

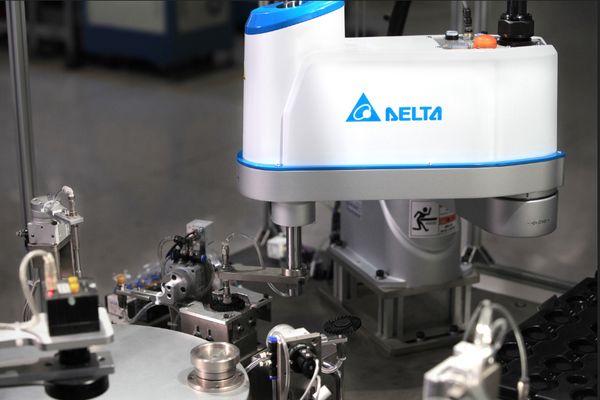

Delta controls the extrusion pipe diameter with its Hybrid Energy Saving System (HES) and servo systems. With the integration of the All-electric Injection Molding Machine AOP Series which provides a control interface for parameter setting and the PC-based Host Motion Controller MH2 Series which has a built-in EtherCAT, users can easily perform synchronous multi-axis motion control including the core pin axis, wall thickness control axis, and mold clamping axis.

Delta’s highly efficient extrusion blow molding machine solutions provide the following benefits:

˙ Flexible programming

˙ A PAC platform for quick response

˙ Integrated wall thickness control

˙ All electric and hybrid operation

Delta’s extrusion blow molding machine solutions integrate all-electric controller, servo systems, and the HES system for high accuracy and stability, and powerful hybrid mold clamping

Delta’s extrusion blow molding machine solutions integrate all-electric controller, servo systems, and the HES system for high accuracy and stability, and powerful hybrid mold clamping