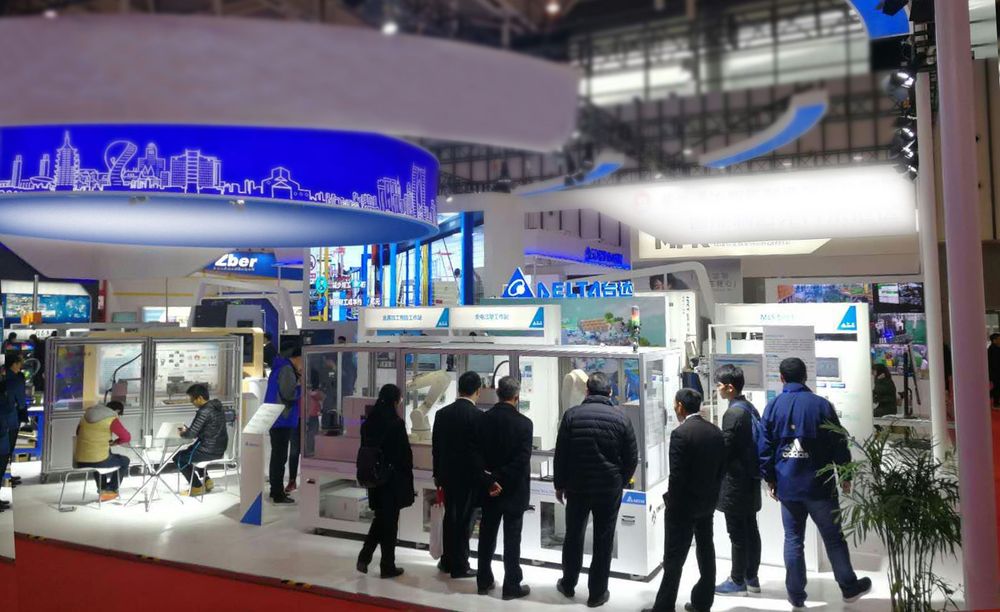

During December 6-8, the 2017 World Intelligent Manufacturing Summit was held in Nanjing. Delta unveiled its smart manufacturing blueprint, in line with the "Manufacturing Transformation Featured in Collaboration and Innovation", to once again present the brand new "Smart Manufacturing Demonstration Line". The production line consists of 3 units of robots which form a workstation, connecting the surrounding equipment, a manufacturing execution system (MES) ordering system, and a Production Management & Visualization Platform (DIAMMP). It produces gifts engraved with the names of guests, and demonstrates the smart manufacturing of small-volume large-variety and mixed-line production.

Other highlights of the Delta exhibition include:

MES Smart Manufacturing Solution: User issues an order from the cloud information level, and after the factory receives the order, MES shall assign a process, and deliver the command to the host controllers of various production equipment, meanwhile recording, tracking, and analyzing all the production processes and equipment operation.

Factory Energy Saving & Monitoring Solution: It displays equipment operation status with graphs and data on SCADA, and efficiently monitors and controls the factory system equipment and manages the energy with Delta DIAEnergie energy management system.

Smart Equipment Solution: The all-in-one smart equipment includes a smart metal processing station, smart plastic processing station, a smart packing station, and a smart assembly and inspection station.

Delta unveils smart manufacturing blueprint at WIMS 2017 with "Smart manufacturing demonstration line"