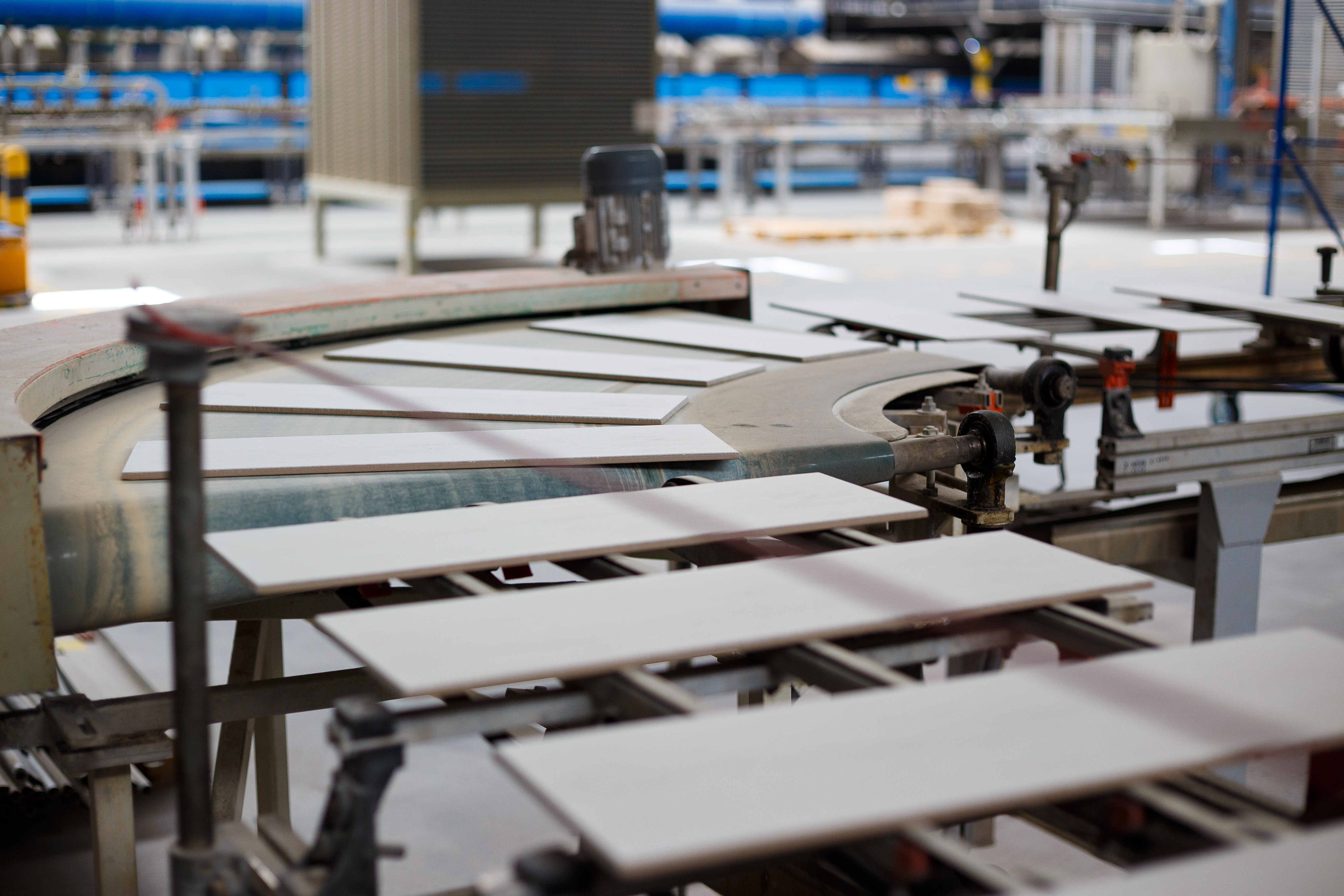

Simplicity of motion control programming eases implementation of automated tile manufacturing equipment As a material for the home, workplace, or retail environment, tiles provide a robust and durable surface that can be both practical and elegant. As good conductors of heat, they adapt to the room’s warmth and help keep your home feeling cozy. Companies such as E.G. Sistemi s.r.l YES! are focused on system integration for the manufacturing equipment used in today’s highly automated ceramic industry. Situated in the “ceramic valley” in Maranello, northern Italy, they have recently retrofitted the multi-axis airless station with independent translators. Such equipment is coupled with a conveyor belt that delivers tiles to the airless station where they are processed according to one of a number of recipes. Such a dirty and dusty environment demands reliable multi-axis motion controllers and motor drives for the servos.

At the core of the implementation is a Delta DVP50MC series motion controller. Capable of controlling up to 24 axes in one millisecond, this solution supports both single-axis motion instructions, such as velocity, torque, and position, as well as multi-axis instructions, such as electronic cam (E-CAM) and gear. The DVP50MC is also responsible for controlling the conveyor belt. For this task, the team selected an MS300 series compact vector control drive to couple with the chosen motor. Remarkably space-saving at 40% smaller than comparable drives, the MS300 simplifies installation and wiring within the electrical cabinet. Rounding off the implementation is a 15-inch, DOP-100 series HMI that enables the operator to select the correct recipe for the tiles being manufactured. Part of Delta’s advanced design offering, this display provides a narrower frame that leaves more room for displaying the input controls and system feedback.

The combination of easy-to-program motion controllers and excellent support from Delta’s support team ensure that Maranello retains its status as the place to source outstanding tiles. Delta’s automated solutions improve the production efficiency of tile manufacturing equipment.

Delta’s automated solutions improve the production efficiency of tile manufacturing equipment.

A complete smart production line for easy management of razor factories For many men, electric razors are an indispensable daily necessity, whether they are traveling or quarantined at home. New functions and models continue to be released to satisfy their changing needs.

Designs for razors are all different but they mainly consist of 5 basic parts: blade, protective cover, case, gear mechanism, and motor. The structure contains dozens or even hundreds of mechanical parts. If production is dependent on manual assembly, not only is it time consuming, it is difficult to ensure precision and quality pass rate. Therefore, Delta created an automated production line for electric razors in China, presenting the undoubtedly powerful effects of smart solutions. Delta robots, machine visuals, PLC, server systems, network communications, and other automated equipment form the automated and smart production line. It is able to simulate the complex operations of human hands with better efficiency, precisions, and endurance in limited spaces.

The structure of the automated production line for electric razors includes: motor assembly, case mechanism, cover assembly, stand, and blade assembly. With the highly automated production line, the production time needed for one electric razor could be shortened from 5 minutes to 2 minutes, and only requires one fifth of the labor. The quality pass rate of the products can also be dramatically improved. The full use of Delta's automated equipment in production can ensure digitized management of the entire process and create a foundation for future cloud data processing by the clients, making plant management easier and more convenient. The structure of the automated production line for electric razors includes: motor assembly, case mechanism, cover assembly, stand, and blade assembly.

The structure of the automated production line for electric razors includes: motor assembly, case mechanism, cover assembly, stand, and blade assembly.