Delta introduces “Smart Manufacturing Solution Packs”

In the manufacturing industry, the ultimate goal of smart manufacturing is to achieve seamless software-hardware integration and maximize the value of data, while building a customer-oriented, highly operationally efficient, and well-prepared enterprise. During their transformation, however, there are numerous goals at each stage. Unclear smart manufacturing plans and steps confuse most manufacturers and make them hold back. It is challenging to connect a large variety of complex systems while upgrading production lines. How to prevent information silos from occurring and integrate internal processes and data are the keys to implementing smart manufacturing.

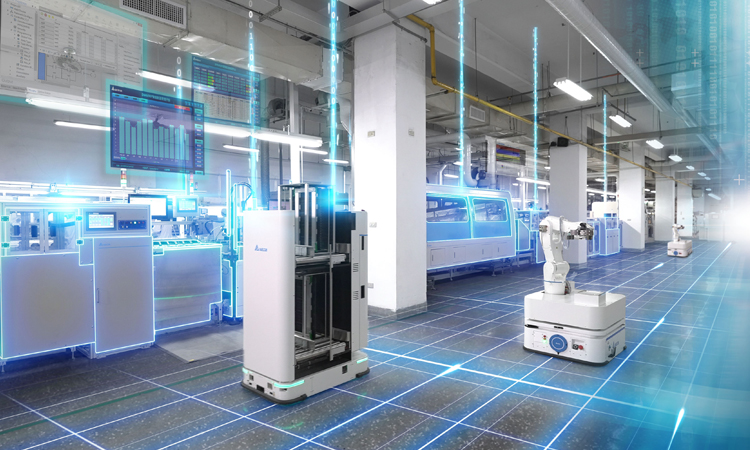

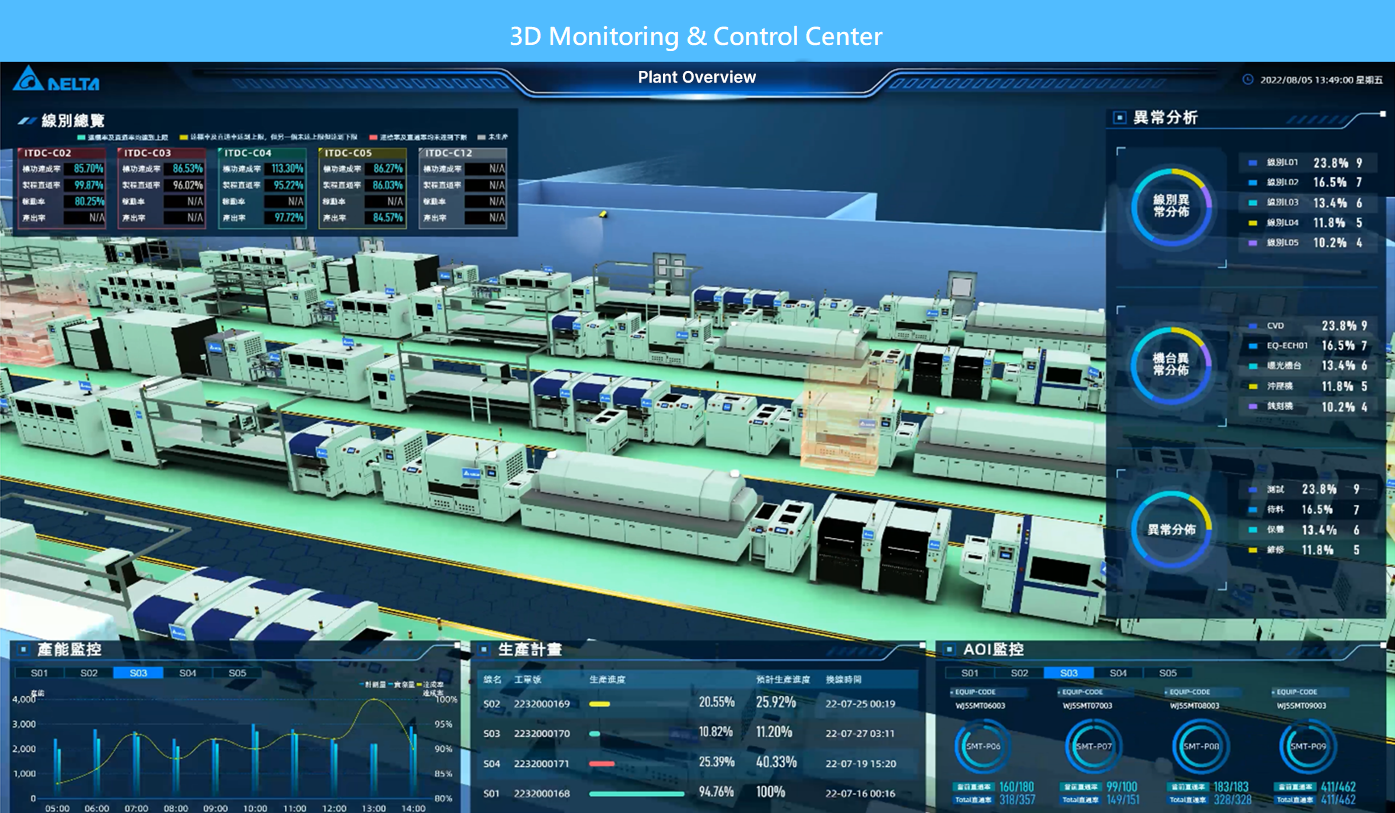

Delta has already implemented smart manufacturing at its worldwide plants. With years of solid experience guiding manufacturers in production upgrades, Delta has introduced its Smart Manufacturing Solution Packs. On the basis of customer needs and industry standards, Delta integrates domain know-how and best practices of production management in software, establishing comprehensive smart manufacturing solutions for the convergence of OT, Edge, and IT layers. The OT layer contains components such as controllers, drives, sensors, and more, whereas the Edge layer includes systems like manufacturing execution, quality control, and energy management. In terms of the upper IT layer, it involves a monitoring and control center, cloud computing, and data analysis platform for managers to conduct in-depth analysis and decision-making.

Integrate DIAAuto platform and DIAMES system to establish a comprehensive smart manufacturing blueprint

Delta Smart Manufacturing Solution Packs consist of two key systems: Automation Integration Platform DIAAuto and Manufacturing Execution System DIAMES. Both are considered important elements in smart manufacturing architecture. Through standardized communication foundations, smart manufacturing systems are expandable and embedded with various new functions. Standardized communication also enables manufacturers to track data on CO2 emissions, decentralized production, and centralized management, achieving seamless integration and connection of multiple systems.

Delta provides specific solution packs for various industries such as electronics assembly, plastic injection molding, precision machining, semiconductors, machine building, and more. With comprehensive and flexible product packages, manufacturers can purchase either a complete system or certain products based on their transformation plans and needs. What’s more, Delta offers consulting, system optimization, and integration services to help customers build a smart manufacturing factory and enhance their business resilience.

In the manufacturing industry, the ultimate goal of smart manufacturing is to achieve seamless software-hardware integration and maximize the value of data, while building a customer-oriented, highly operationally efficient, and well-prepared enterprise.

In the manufacturing industry, the ultimate goal of smart manufacturing is to achieve seamless software-hardware integration and maximize the value of data, while building a customer-oriented, highly operationally efficient, and well-prepared enterprise.

Delta’s Smart Manufacturing Solution Packs provide managers with a monitoring and control center for in-depth data analysis and decision-making, helping customers build a smart manufacturing factory.