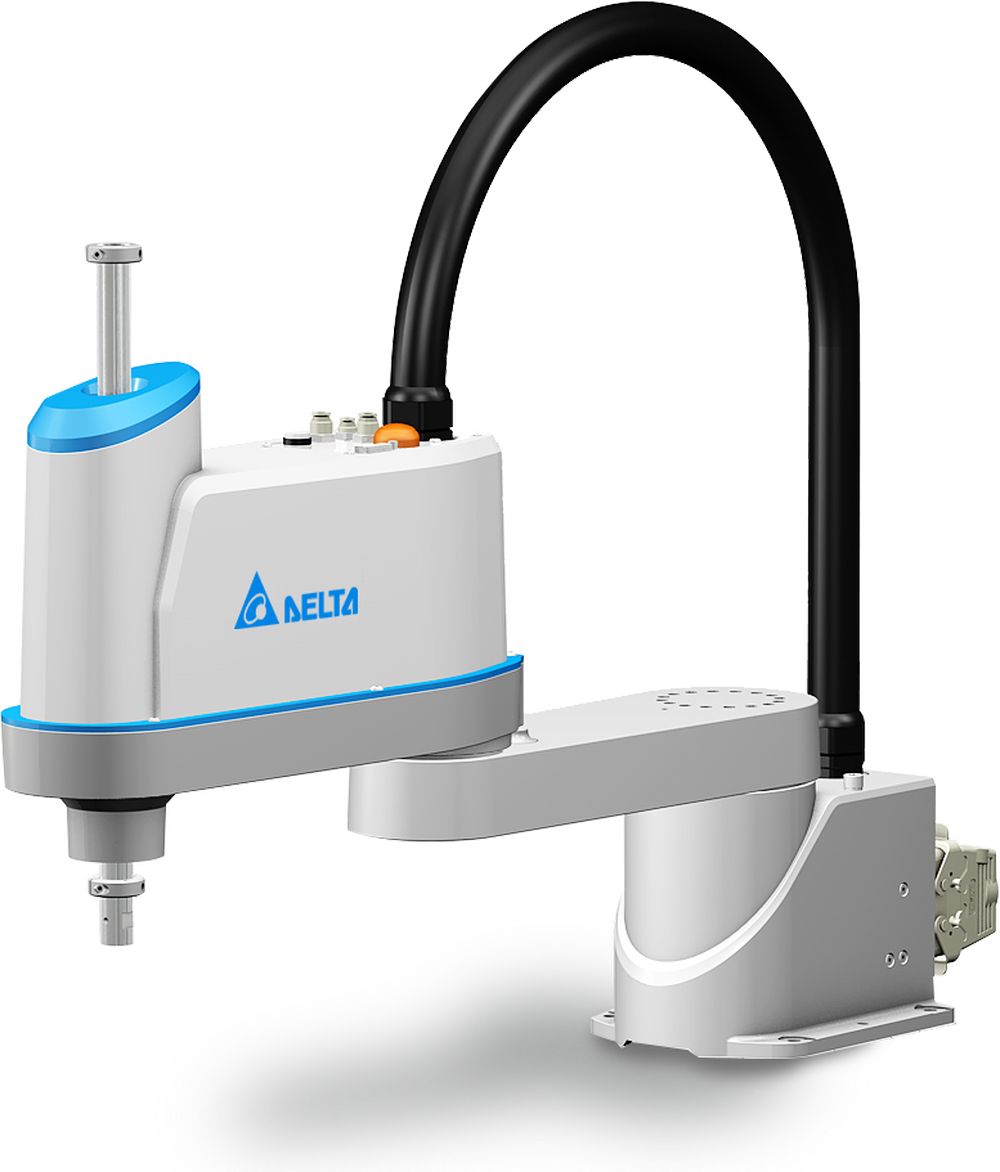

In the wet tissue packet, there is a dust-proof cover, which can be repeatedly opened and closed, making it very convenient to use. In the fitting and assembly process of wet tissue packaging and the cover, because axillary materials vary in types and size difference and require high assembly accuracy, there exists a certain degree of difficulty. To meet the needs of a certain manufacturer, Delta customized a solution with SCARA industrial robot DRS60L series matched with visual software DMV-LIB as the core, which has improved the production efficiency.

In the traditional process of wet tissue cover, the early stage of production cannot meet the requirements of high-speed and high-precision. Delta has launched the customized solution with SCARA industrial robot DRS60L series matched with visual inspection software DMV-LIB as the core, which makes full use of the functions of the robot DRS60L series’ synchronous tracking and automatic planning of movement track in machining and its good coordination with the machine vision system, so as to quickly locate and grab the wet tissue cover and increase speed and accuracy. This solution enables convenient, accurate and quick positioning of the wet tissue cover delivered by applying Delta’s visual inspection software DMV-LIB and the powerful visual monitoring algorithm.

SCARA industrial robot DRS60L series can quickly locate andgrab the wet tissue cover and increase speed and accuracy

SCARA industrial robot DRS60L series can quickly locate andgrab the wet tissue cover and increase speed and accuracy

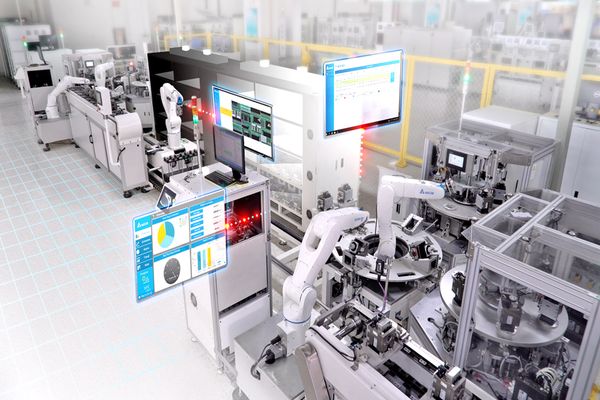

Through the actual test of a wet tissue manufacturer, the solution can significantly increase the production accuracy and speed. Delta’s comprehensive solution of “SCARA industrial robot + visual inspection system” has been widely applied. In the packaging industry, this solution can be used in different process links of the commodity production, such as assembly, transplanting and testing, and can assist the packaging industry in realizing the efficient and intelligent upgrading of the production line.