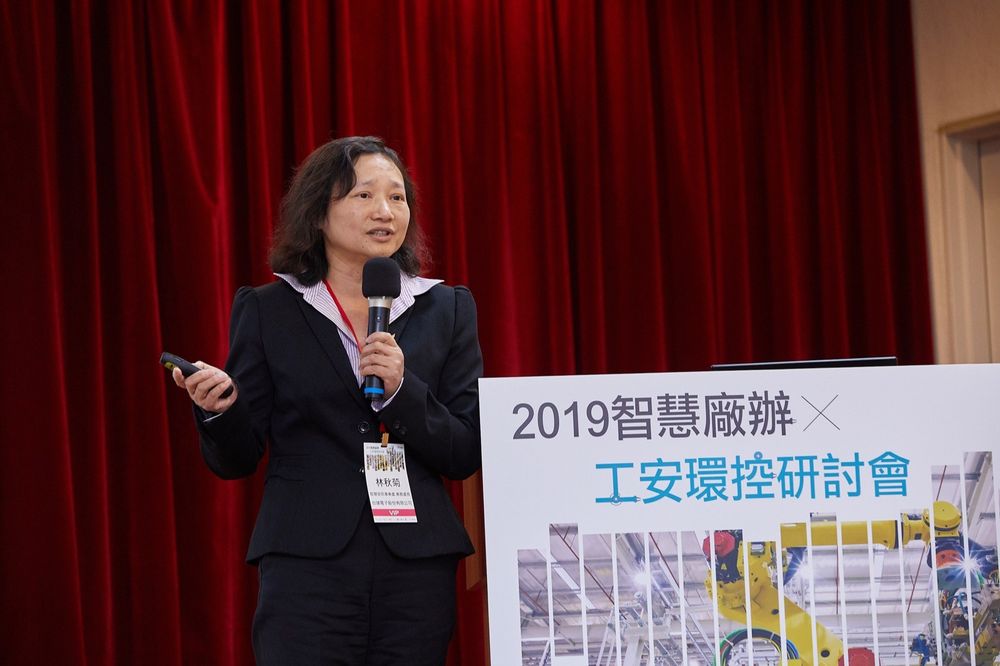

Delta recently participated in the “2019 Forum on Smart Factory x Industrial Safety and Environmental Control” organized by DIGITIMES. The forum attracted nearly 150 professionals in factory operations and property management to attend. Speakers mentioned that smart factories should be built on a smart factory infrastructure, which includes industrial safety and environmental control. Delta shared several success stories on factory buildings and security during the forum, and stressed that under an open architecture a single management platform with multi-task integration can achieve a linked synergy between systems and reduce integration and labor costs by 20%, which prompted audience discussion.

Charlene Lin, Business Development Chief of Delta’s Surveillance Automation Solutions Business Division, shares Delta’s success stories at the forum

Charlene Lin, Business Development Chief of Delta’s Surveillance Automation Solutions Business Division, shares Delta’s success stories at the forum

Delta's smart factory solution emphasizes an open architecture, where a single platform and multi-task integration allow different systems to be integrated onto the platform. This solution achieves a linked synergy between the systems, reducing integration and labor costs by 20%, and improving the efficiency of factory management. Most factory management systems work independently and have not been integrated, so they are unable to achieve linked synergies between systems. Charlene Lin, Business Development Chief of Delta’s Surveillance Automation Solutions Business Division points out: “Infrastructure establishment costs cannot be shared, and when unexpected situations occur, only experienced managers can be relied on for their inter-system operation judgment. The high manpower management costs can be difficult to bear. Delta's smart factory solution uses mature technologies to help build smart office and factory environments with high degree of automation, tight security, in-depth intelligence and comprehensive management.”