With the rapid advancement of 5G, AI, and cloud computing, smart production line upgrades has become essential for boosting competitiveness in the manufacturing industry. Enterprises are increasingly adopting management software and building IIoT architectures to drive automation and smart production lines.

Delta, with over 30 years in the industrial automation field, continues to advance the vision of "Digitized Automation for a Changing World" and demonstrate outstanding achievements in smart production line upgrades. By integrating advanced technologies, Delta has significantly boosted production efficiency and capacity, both in its own global plants and for clients. These innovations enable efficient, transparent, and flexible manufacturing management in the era of smart manufacturing.

Partners with Delta for smart production line upgrades

Paonan Biotech Co., Ltd., founded in 1985, specializes in orthopedic and spinal devices/implants. With fast-growing market demand, Paonan’s traditional labor-based management and current scale can no longer sustain its expansion. To enhance efficiency and optimize operations, the company is embracing digitalization and smart systems.

David Yeh, chairman of Paonan, stated: "After a thorough comparison, we chose Delta as our partner. With their experience in digital transformation, we will be great partners in making smart upgrades." This collaboration strengthens Paonan’s competitive edge and accelerates its transition to smart manufacturing.

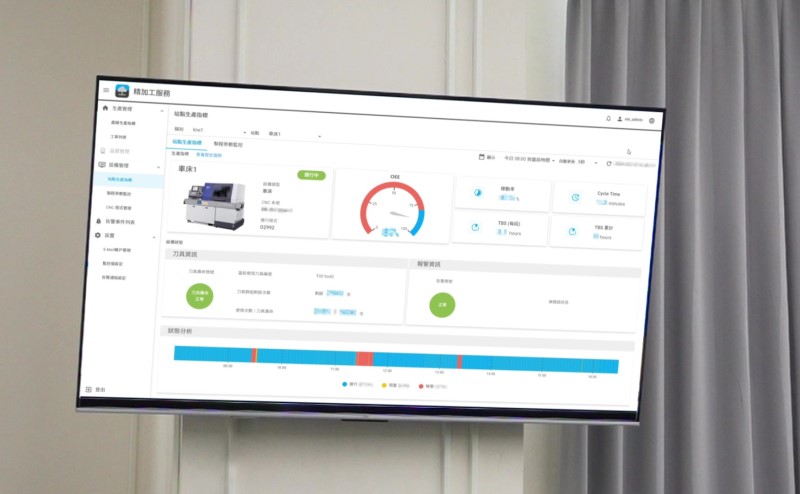

Boosting production efficiency and management transparency with Delta' s intelligent system

Before implementing Delta’s DIAEAP-PMM (Precision Machining Management Platform), Paonan’s precision machining relied heavily on skilled technicians for equipment commissioning and process tuning, making quality dependent on individual expertise. This manual-based operation lacked comprehensive data, limiting traceability and process replication. After adopting Delta’s Equipment Automation Program DIAEAP-PMM (Precision Machining Management Platform), Paonan saw significant improvements in production efficiency and management transparency. Quality control and equipment maintenance became more automated, shifting the production focus from manual expertise to data-driven system management. Real-time data analysis boosted production yield per person by 30%, reduced operational costs by 20%, and enhanced quality monitoring efficiency by 40%. After adopting Delta' s Equipment Automation Program DIAEAP-PMM (Precision Machining Management Platform), Paonan has automated quality control and equipment maintenance.

After adopting Delta' s Equipment Automation Program DIAEAP-PMM (Precision Machining Management Platform), Paonan has automated quality control and equipment maintenance.

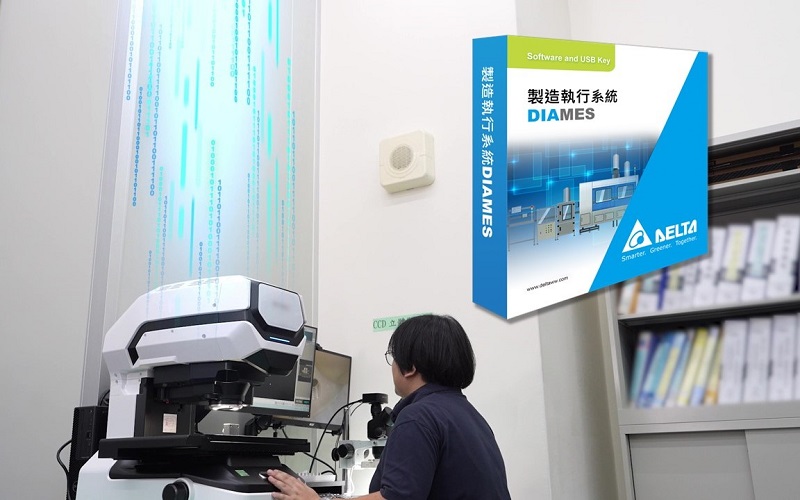

Paonan also integrated Delta' s Manufacturing Execution System DIAMES, which precisely monitors manufacturing processes, optimizing workflow from order intake to final product output. Inspection measurement personnel can upload real-time data and get immediate results, which enhances monitoring efficiency by 40%. Additionally, paperless operations enables instant access to inspection reports. With real-time dashboards and data visualization tools, managers can monitor production remotely, which leads to a 45% increase in overall efficiency.  With Delta' s Manufacturing Execution System DIAMES, inspection measurement personnel can upload real-time data and get immediate results, enhancing monitoring efficiency by 40%.

With Delta' s Manufacturing Execution System DIAMES, inspection measurement personnel can upload real-time data and get immediate results, enhancing monitoring efficiency by 40%.

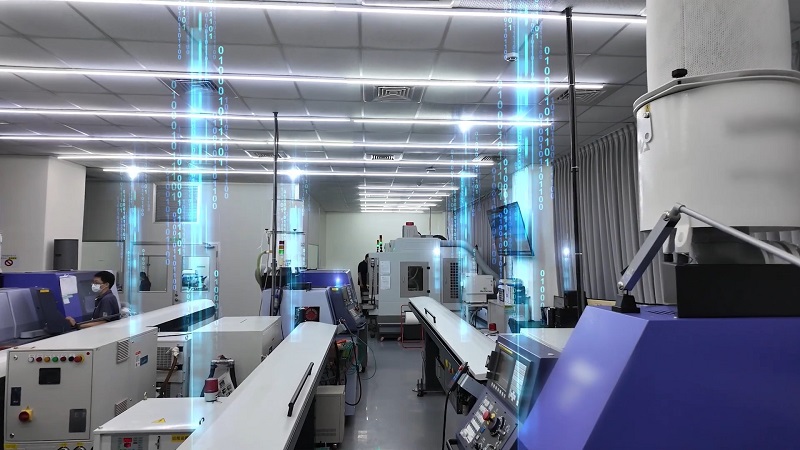

Paonan partnered with Delta and successfully implemented smart software systems, standardizing production and enhancing efficiency and quality management.

Paonan partnered with Delta and successfully implemented smart software systems, standardizing production and enhancing efficiency and quality management.

Smart solutions drive global supply chain integration

Paonan, in partnership with Delta, has successfully implemented smart software systems, standardizing production and enhancing efficiency and quality management. Moving forward, this collaboration will expand beyond Taiwan, seamlessly integrating Paonan into the global supply chain, while advancing the future of smart manufacturing.

Watch the video to explore Deltas solution and success story in action: https://youtu.be/L5vHztbofxE?si=NVkQrVxOw4YvXxLh