To enhance screen-printing precision and quality, Delta recently provided an automated and highly efficient screen printing inspection solution for an MLCC manufacturer in China. The manufacturer’s screen-printing machines caused ragged edges or white dots on the printed patterns, or abnormal printing results of electrode positioning points due to long-term use. In addition, the manufacturer needed to implement 1st-piece inspection before mass production, where the 1st printed and slit ceramic film is inspected under a microscope before mass production, which can be time-consuming.

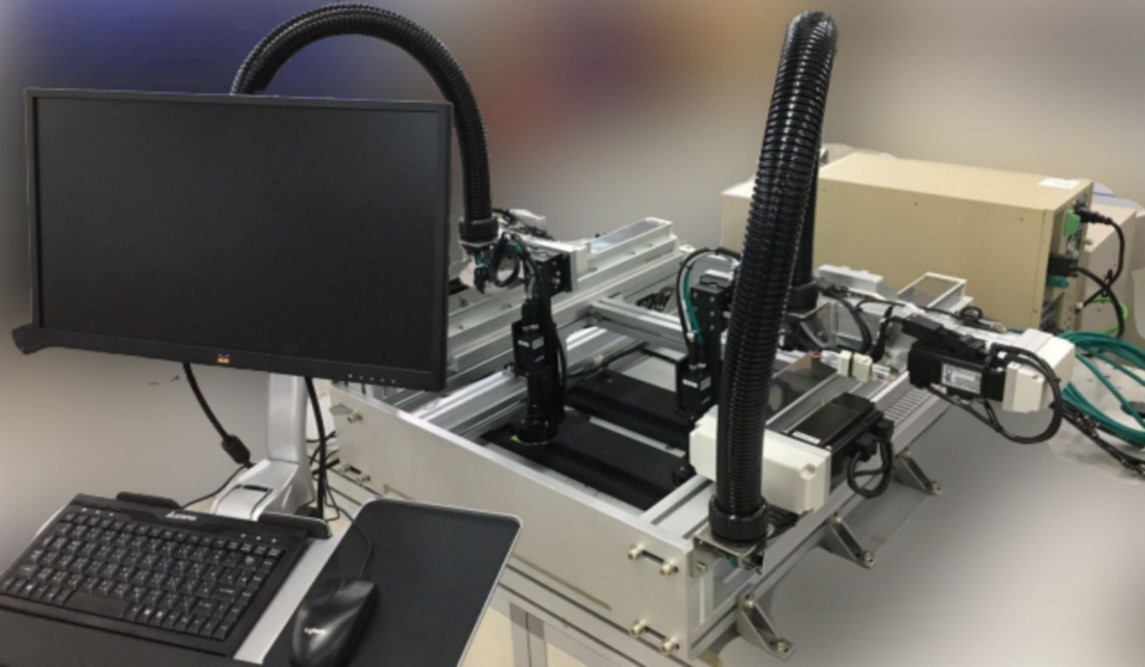

Delta has developed screen-printing inspection modules with its extensive experience in highly precise inspection. The modules execute automated multi-axis control by using Delta’s self-designed DIAVision VGR Vision Software (for Robots and Motion) and motion controllers connecting via EtherCAT. The DIAVision VGR can achieve fast inspection speeds of up to 1,440 pieces per hour with efficient defect counting and precise size measurement.

With its extensive experience Delta has developed screen-printing inspection modules that execute automated multi-axis control via EtherCAT for diverse in-process workpiece inspection.