In the age of the Internet of Things, chips stand at the heart of technological innovation. As it strives for heightened precision and efficiency, the semiconductor manufacturing industry is ushering in a new wave of smart transformation. Responding to ever-increasing demands, Delta provides technological prowess that enhances wafer production quality and capacity, supercharging the semiconductor supply chain.

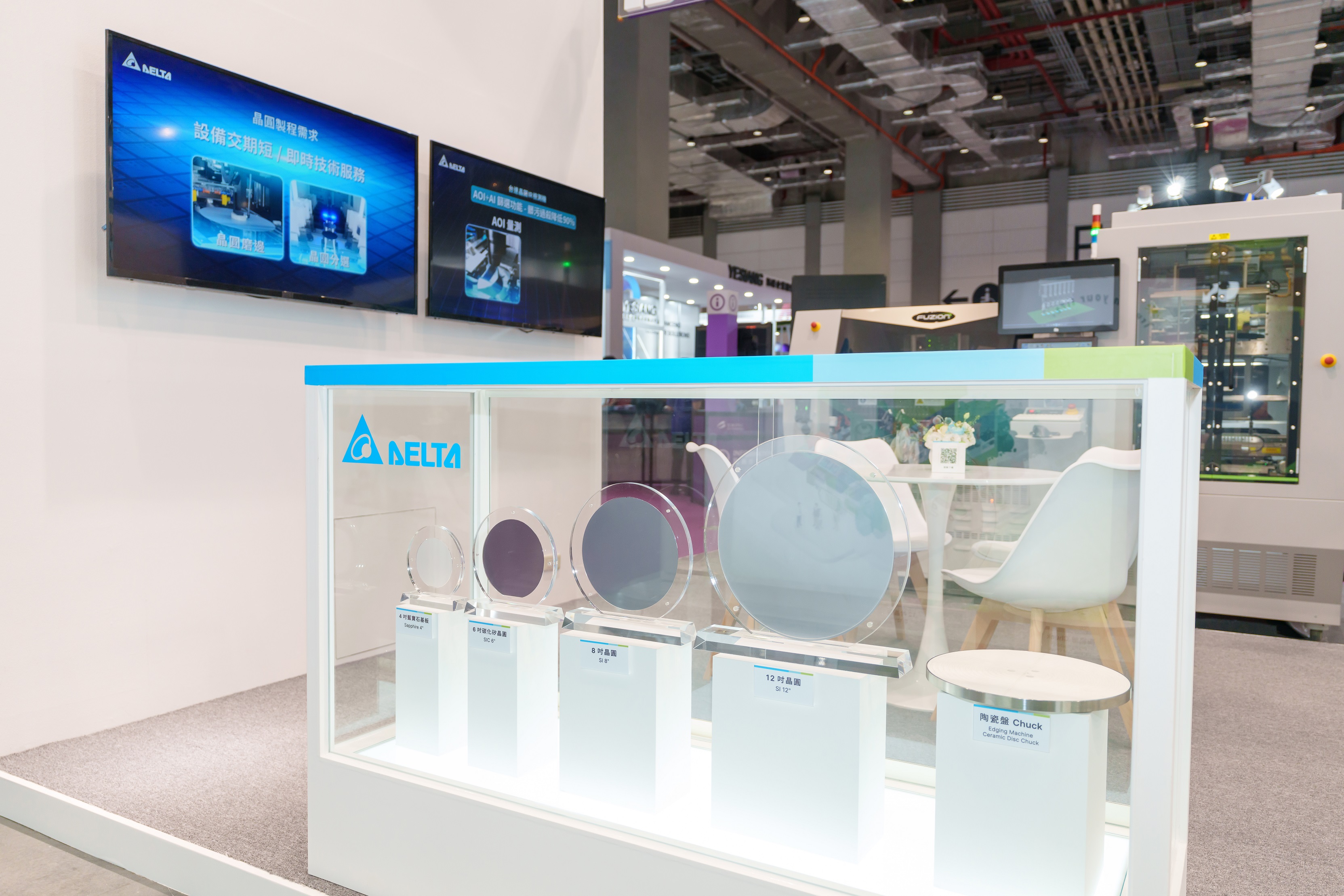

Silicon wafer manufacturing is the upper stream of the semiconductor supply chain. Silicon ingots are sliced into wafers, and a grinding wheel polishes each wafer to extreme smoothness. This process is called edge grinding. Edge grinding is critical in the making of semiconductor chips. Subpar grinding efficiency, accuracy, and stability can directly impact the downstream manufacturing processes.

Three main challenges occur with previous edge grinding equipment. Firstly, controlling the precise contact position of the wafer and the grinding wheel is not an easy task. Secondly, engineers often devote considerable time to adjusting edge grinding parameters to fit different wafer processes. Lastly, the need to acquire separate production and measurement machines may lead to long and inefficient production lines.

To enhance the efficiency, precision, and stability of wafer manufacturing, Delta's Wafer Edge Grinding Machine integrates robust hardware and software technologies. The software interface offers intuitive visualization with parameters for notch and single/double flat grinding paths. It reduces commissioning time by providing parameters such as wafer cassette paths, grinding wheel rotation speed, and grinding time. Moreover, technicians can directly monitor contact positions when changing grinding wheels or production lines on the main screen. Such functions greatly enhance the positioning precision of wafer grinding.

The hardware design of Delta’s Wafer Edge Grinding Machine also aims at higher precision and stability. The machine is equipped with a micrometer-scale industrial camera, which locates the center point of the wafer and ensures precise positioning during material feeding. Delta also offers an edge profile measuring module, integrating manufacturing and measurement for a streamlined workflow.

The grinding wheel in contact with the wafer is a critical component. Delta's Wafer Edge Grinding Machine is equipped with built-in sensors that detect the grinding wheel condition. It alerts technicians before wear and tear, thus reducing unexpected equipment failures. The fast wheel replacement feature reduces downtime by 80% and enables quick restoration of grinding equipment operation, greatly enhancing equipment utilization.

In the wake of rising semiconductor demand, ensuring equipment quality is key to enhancing production efficiency. The intelligent integration of hardware and software in Delta's Wafer Edge Grinding Machine boosts equipment capacity. Delta’s advanced products serve as solid support for a smart manufacturing future with the semiconductor manufacturing industry.

Delta's Wafer Grinding and Inspection Solutions include a Wafer Edge Grinding Machine, Wafer Edge Profile Measurement Machine, Wafer Sorter, and IR Pinhole Inspection Machine.