Delta’s Green Pledge: 100% Waste Conversion Rate*2

Imagine a world where all waste becomes a resource—how wonderful would that be?

For companies, the journey toward true "zero waste" is still long, as conditions in product design, new materials, industrial processes, business models, regulatory environments, and public infrastructure are not yet fully aligned. However, "zero waste to landfill " is a tangible goal that can be achieved today and verified externally.

Delta is committed to achieving "zero waste to landfill " across its facilities by employing scientific management and technological solutions. This involves minimizing waste generation at the source, improving resource utilization efficiency, and reducing waste's environmental impact. The core concept of "zero" entails avoiding the energy wasted in landfilling and incineration by implementing reduction, recycling, reuse, and energy conversion processes. This not only conserves land resources but also mitigates environmental pollution risks.

Delta pursues sustainable resource utilization and actively aligns with the United Nations Sustainable Development Goals (SDGs). The company has set a goal of achieving a 100% waste conversion rate by 2025. This means that every piece of waste paper and every scrap of metal will be effectively reused rather than buried in landfills.

*1: https://www.unep.org/zh-hans/resources/Global-Resource-Outlook-2024

*2: Waste conversion rate = (Reuse + Reduction + Recycling + Repurposing + Waste-to-Energy Recovery + Anaerobic Digestion + Biofuel + Composting) / Total Weight of Waste Generated; the proportion of waste-to-energy recovery must be less than 10%.

Waste Management: Sorting, Reduction, Reuse, Recycling, and Regeneration

At Delta, waste is classified as resource, hazardous, or general waste, each managed scientifically: resource waste is recycled, hazardous waste is handled safely, and general waste is sent to designated facilities. Since 2016, Delta's Energy and Water Conservation and Waste Reduction Management Committee, under its ESG Committee, has set reduction targets and strategies. Between 2018 and 2023, Delta implemented 439 initiatives, cutting waste by 17,700 tons. Through training and communication, employees are educated on waste classification and solutions, supported by the group’s Internal Carbon Pricing (ICP) fund.

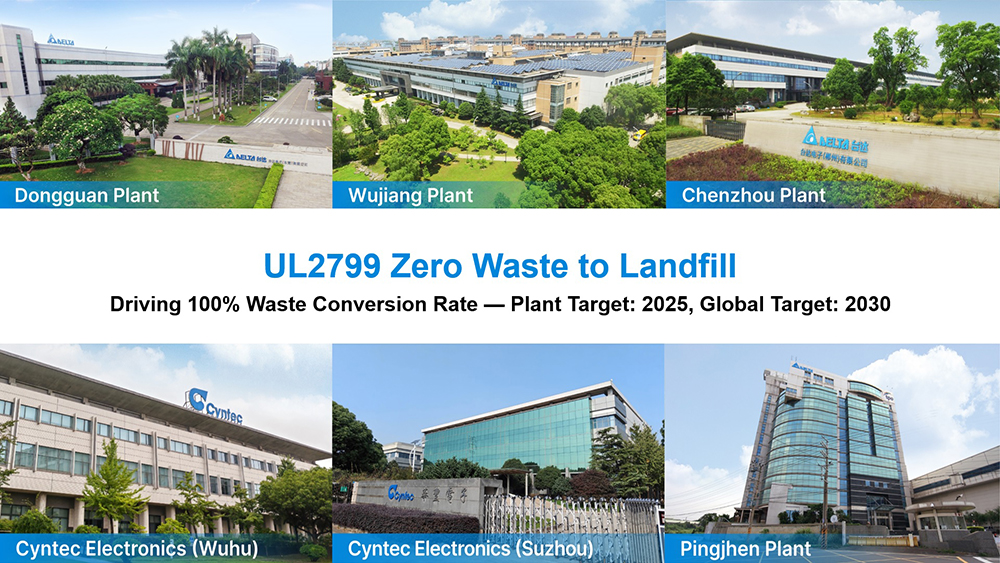

Delta aligns with international standards, introducing UL2799 Zero Waste to Landfill certification at its Dongguan site in 2019*3. By 2024, all major production facilities had adopted UL2799*4, with six achieving platinum certification. Over five years, Delta scaled its efforts globally, demonstrating dedication to sustainable resource use and zero-waste manufacturing.

*3: UL2799 is a certification standard for Zero Waste to Landfill. It requires enterprises to ensure compliance management, verification, and auditing of all waste streams within the organization. The standard verifies that waste undergoes processes such as reduction, recycling, reuse, and energy recovery to prevent landfill disposal or incineration without energy recovery. Certification is granted when the overall resource conversion rate reaches 90% or higher.

*4: The primary production facilities include Dongguan, Wujiang, Wuhu, and Chenzhou plants in mainland China; Plants 1, 3, 5, 6, 7, Turbon 1, and Turbon 2 in Thailand; Taoyuan Plants 1, 2, and 5, as well as Pingzhen Plant in Taiwan; Cyntec (Hsinchu and Tainan) plants; and Huanteng and Huafeng plants (Wujiang and Wuhu).

Dongguan, Wujiang, Chenzhou, Pingzhen, Huafeng Wuhu, and Huafeng Wujiang Factory have all obtained UL2799 platinum level certification.

Dongguan, Wujiang, Chenzhou, Pingzhen, Huafeng Wuhu, and Huafeng Wujiang Factory have all obtained UL2799 platinum level certification.

Waste data is systematically tracked on Delta's ESG platform, supported by facility documentation and audits of disposal providers. Waste sources are analyzed to identify reuse opportunities. Measures like hot runner mold development, reduced solvent use, and lowering sludge moisture content minimize waste and enhance recycling. Facilities replace single-use cardboard with reusable plastic boxes, repurpose scrap metals, and increase plastic utilization, showcasing Delta’s commitment to waste reduction.

Delta extends waste reduction across the value chain, working with suppliers and recyclers to reuse materials like cardboard, trays, and bags. These materials are reprocessed into packaging, completing a circular loop. Delta collaborates closely with suppliers to advance a circular economy and achieve meaningful waste reduction.

In 2023, Delta’s operations generated 66,626 metric tons of waste, with 65,960 tons converted—achieving a 99% conversion rate*5 and a 3.5% total waste reduction. Initiatives reduced 450 metric tons of waste, saving USD 920,000. UL2799-certified projects avoided 10,815 metric tons of CO₂ emissions by replacing cardboard boxes, reducing silicon steel, and reusing materials*5.

*5: According to the emission factor of Simapro (Steel, chromium steel 18/8 {GLO}| market for | APOS, U)

To extend producer responsibility and promote circular economy practices, Delta launched a supply chain in 2020 using waste edge materials from circuit board production. Collaborating with various partners, Delta developed circular construction materials used in green spaces, the Taoyuan Biogas Center, and exhibitions, highlighting its achievements in waste management and sustainability.

In the 2024 CIIE, wood-plastic composite has been showcased on-site, utilizing recycled materials as display stands.

In the 2024 CIIE, wood-plastic composite has been showcased on-site, utilizing recycled materials as display stands.

Net-Zero by 2050: a commitment to a green future

Achieving the long-term Science-Based Targets (SBT) for net-zero emissions by 2050 is Delta's pledge to the future. Delta practices sustainability through action and leads the way with innovation. In response to the challenges of reducing Scope 3 carbon emissions for the net-zero target, Delta actively adopts circular economy practices and product carbon footprint methodologies. Collaborating with its supply chain, Delta drives process circularity and waste reduction, opening a new chapter in zero-waste manufacturing and co-creating a sustainable future for our planet.