Turning academic frontiers into industrial capabilities: Delta’s robotics strategy takes shape

“A robot is essentially an integration of mechanical engineering, electrical engineering, and computer science.” As Delta has formally entered the emerging technological domain of robotics, Dr. Pei-Chun Lin opened the interview with this single, straightforward sentence, helping the interview team quickly grasp the engineering essence of robotics.

Reflecting on his academic journey, Dr. Lin began his research in robotics in 2000 while pursuing his doctoral degree in the United States. After returning to Taiwan, he joined his alma mater, National Taiwan University, where he established the Bio-inspired Robotics Laboratory (BioRoLa). He smiled as he recalled, “When I was a doctoral student, I saw a research project that mimicked insects by building six-legged robots that could move across the ground. I found it fascinating—only to realize later that the research was actually based on studying cockroaches.” This seemingly light-hearted memory reflects more than two decades of accumulated research, spanning from observing how living organisms move and perceive their environments to translating those principles into engineering design and control architectures.

A cockroach-inspired six-legged robot developed under the Dr.’s supervision during his time at the NTU BioRoLa.

Photo source: Artificial Intelligence for Intelligent Manufacturing Systems Research Center (left); NTU BioRoLa.

After joining Delta in August 2025, Dr. Lin began transforming years of academic research experience into industrial technology directions that could be implemented and scaled over time. He has helped Delta initiate a systematic, long-term robotics R&D strategy in an entirely new field. At present, the Delta Robotics Innovation Center (DRIC) is structured into six technical groups, focusing on robot design, sensing technologies, cognitive intelligence (the “cerebrum”), athletic intelligence (the “cerebellum”), digital twins, and system integration. These efforts aim to gradually build core capabilities that can accumulate over the long term and support industrial applications, with plans for future expansion.

Mobility and manipulation: a dual technology axis focused on mastering movement and task execution

When asked about the market’s strong interest in humanoid robots, Dr. Lin offered a pragmatic response. “Since the Center was established, the question we are asked most often is: Are you going to build humanoid robots?” he said with a smile. Rather than rushing into humanoid robot development, DRIC has chosen to start from real-world task requirements. At this stage, DRIC is concentrating its efforts on two core capabilities: manipulation and mobility. Dr. Lin used the analogy of a robot’s upper and lower body to explain this approach. The lower body is responsible for the mobility platform—including wheeled, bipedal, and quadrupedal configurations—addressing locomotion challenges across different environments. The upper body, by contrast, focuses on dexterous hands and manipulation capabilities, progressing from single-handed to dual-handed operation and extending into tactile perception, with the goal of building modular manipulation technologies.

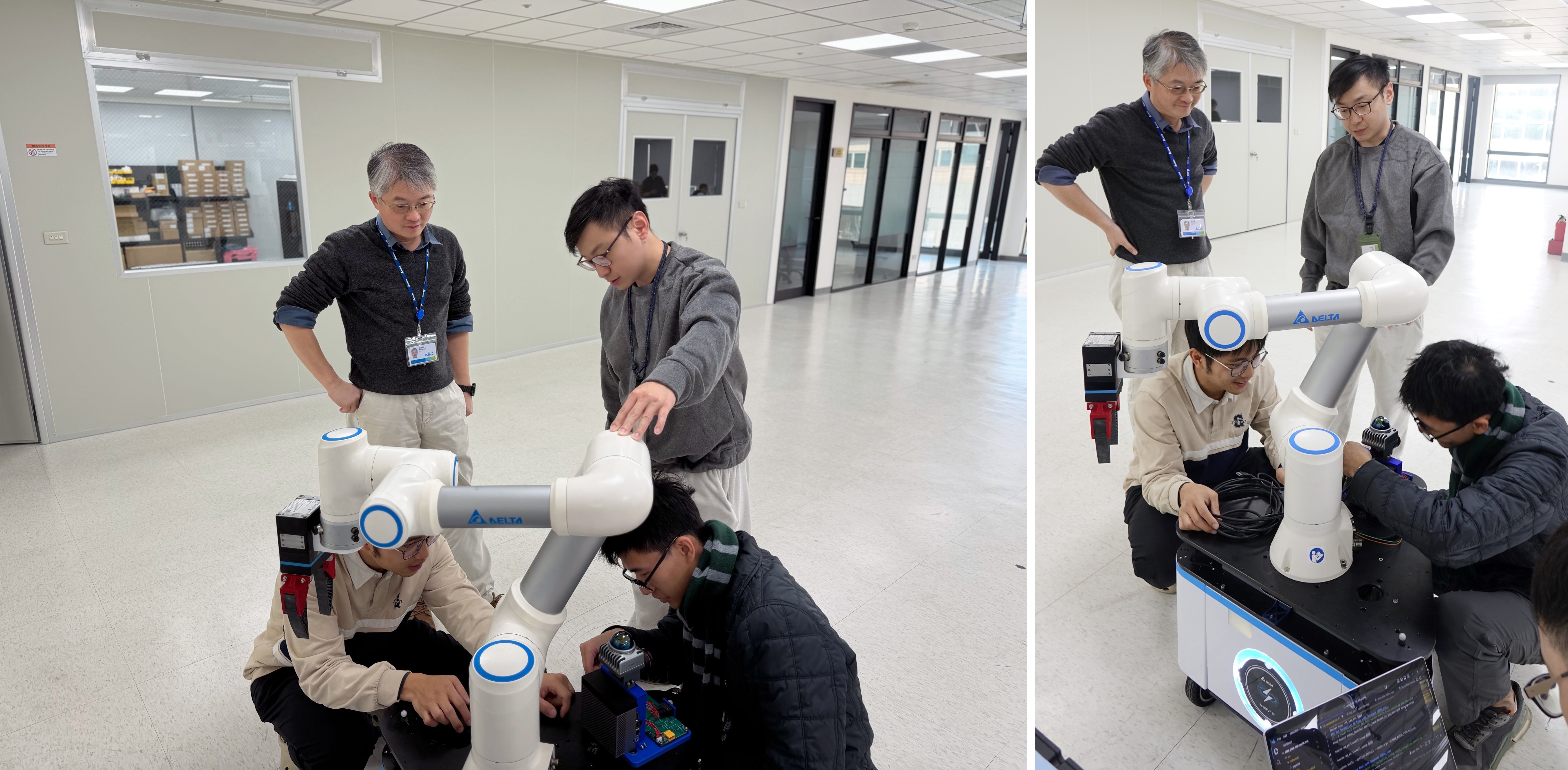

Under this strategy, DRIC conducts research on the upper and lower body separately. Based on Delta’s practical needs, the Center has initially focused on wheeled platforms, while developing manipulation and mobility capabilities in parallel, in preparation for a wide range of future service-oriented applications. “Our advantage is that we can train directly in Delta’s own factories,” Dr. Lin noted. With Delta’s extensive business portfolio and diverse product categories, the Company naturally encompasses a large number of manipulation-intensive tasks, making its factories an ideal environment for validating robotics technologies. On one hand, DRIC continuously refines its technologies through repeated testing in factory environments; on the other hand, it simultaneously considers how these advancements can further enhance factory automation. Looking ahead, these technologies are expected not only to support internal applications but also to evolve into external solutions offered to customers.

Dr. Lin also pointed to a key challenge in using robots today: reaching a designated position is no longer particularly difficult—wheeled robots can do it, and bipedal robots can as well. The real challenge lies in whether a robot can perform its task effectively once it arrives. As a result, manipulation capability has become the most critical area for breakthroughs at this stage. When discussing future applications, his tone noticeably lightened. He smiled and suggested that perhaps one day we may see robots operating in office environments, moving through corridors and working alongside colleagues. Beyond technical considerations, this vision introduces entirely new social science challenges, including occupational safety, information security, regulations, and human-robot interaction, as organizations explore how robots can be naturally integrated into everyday work. These are issues that have rarely been discussed in depth in the past. For this reason, Dr. Lin believes that a world in which humans and robots coexist may be closer than many expect. He also revealed that at the internal technology strategy meeting scheduled for March, DRIC is expected to present its phased progress in both upper-body and lower-body robotics technologies, gradually bringing these possibilities into clearer focus.

The DRIC team will keep expanding, concentrating on six key technologies—robot design, sensing, cognitive intelligence, athletic intelligence, digital twins, and system integration—to develop long-term core capabilities.

Consolidating technological expertise to create a distinctive robot portfolio

“DRIC aims to serve as Delta’s central coordinating unit for robotics research and development,” Dr. Lin explained. During the Center’s early establishment phase, he visited various business units to gain a deeper understanding of existing technologies and production-line needs, helping to identify directions for joint development. “In the long term, we hope robotics will become an integral part of Delta’s business,” he noted. “That will require close collaboration and shared growth across the organization in the coming years.”

These visits also highlighted Delta’s differentiated strengths compared with other companies. Using data center solutions as an example, Dr. Lin described how leaders from multiple business groups—such as ICTBG, PSBG, and FMBG—can jointly participate in customer discussions, demonstrating Delta’s comprehensive technological foundation in critical areas such as power management and thermal solutions. “When we introduce a robot to the market, it represents the combined expertise of multiple business groups,” he said. “That integration is what makes Delta’s robotics offerings distinctive.”

From a technology strategy perspective, business units tend to focus on projects that can be commercialized in the near term, while DRIC concentrates on next-generation—and even next-next-generation—technologies, targeting innovative capabilities that may be applied three to five years into the future. Taking the Industrial Automation Business Group (IABG) as an example, while the business unit focuses on technologies such as electric grippers, DRIC approaches the field through dexterous hands and extends into advanced capabilities such as tactile sensing.

As these technologies gradually mature within the DRIC, they may be transferred across departments or to business units—potentially through a New Business Development (NBD) pathway—to become practical products or solutions. Dr. Lin humbly acknowledged that market competition and real-world feedback ultimately rely heavily on the business units. “This is the first time I’ve truly faced challenges at this level of practical application,” he said.

One of the key focuses of Dr. Lin and the DRIC team is the robots’ manipulation capabilities once they are in position.

A small boat boarding an aircraft carrier: sailing toward a broader future driven by curiosity

Having joined Delta just over four months ago, Dr. Lin described his experience as feeling “like boarding an aircraft carrier from a small boat,” moving from independent academic research into a fully structured corporate organization with clearly defined roles and responsibilities. His focus has been on leading his team in research and technology development that responds directly to the practical needs of the business units. At the same time, he hopes that, in the future, when the market speaks of robotics, DRIC will be recognized as one of the representative corporate research institutes in the field.

This new challenge has also prompted him to reflect on the motivation that has driven him throughout his career: a deep curiosity about “things that move.” “Since I was young, I’ve enjoyed taking apart matchbox cars, remote-controlled vehicles, and mechanical clocks,” he recalled. “I always wanted to understand why they moved.” That curiosity has sustained him through more than 25 years of robotics research. Looking back, he smiled and said that working with robots has truly been enjoyable. He encouraged younger generations to maintain their curiosity and perseverance, and to pursue what they love with courage—trusting that, in time, answers will reveal themselves.