“Driving the smart future: 2019 Delta’s new industrial automation product release” was held in Beijing on August 22. According to General Manager Chen Minren of DGC’s Industrial Automation Business Unit (IABU), “Delta has been in automation for more than twenty years and has accumulated rich experience in the industry. With its strong research and development capability and production process, it provides customers with new general industrial automation products with breadth and depth, satisfying users’ high-end requirements of industrial intelligentization upgrade.” According to General Manager David Tsai of IABG’s Industrial Motion System Business Unit (IMSBU), “Delta adheres to the philosophy of decentralized control in the development of motion control products and solutions. While increasing productivity, it also optimizes the overall control network in smart manufacturing. PC-Based motion controller AX864E series and high-performance servo drive system ASDA-B3 series are proof of Delta’s development of intelligentization.”

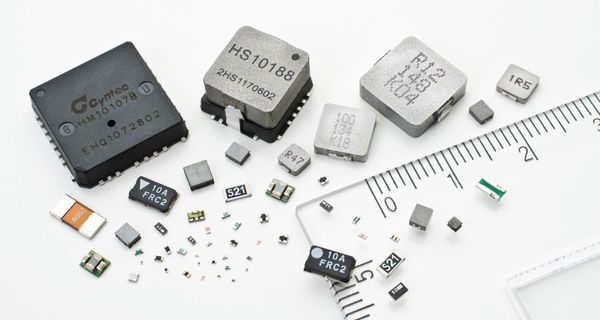

The new industrial automation products launched include:

PC-Based motion controller AX864E series: Delta’s new generation PC-Based motion control product is developed to meet the high-precision processing requirements of intelligentization. It uses CODESYS motion control software platform, currently widely used by machinery and equipment manufacturers, significantly reducing the time and cost incurred by machinery and equipment manufacturers in building the equipment.

High performance servo drive system ASDA-B3 series: small and compact, equipped with powerful loading capacity, uses 3.1 kHz bandwidth +24 bit resolution, and has lowered 40% high response setting time.

Compact vector control drive ME300 series: It is easy to install and user-friendly, and has low maintenance cost, significantly increases equipment production quality and efficiency, and saves manpower and cost.

High-performance universal vector control drive C2000 Plus series: 460V model has a maximum power range of 560kW, significantly increasing loading capacity from 120% to 150%, providing good speed control, torque control, position control and system stability for drive series.

High-speed inverter C2000-HS series: A rated output frequency of up to 1500Hz efficiently enhances inverter’s output current; the size of inverter reduces by 60%, suitable for high-speed requirements in fluid machinery.

Synchronous reluctance motor: IE5 efficiency, energy saving from 5% to 10%, 2 frame size lesser compared to traditional electric motor.

(left to right) DGC’s IABU Inverter Product Director Shi Wenyang, IABU GM Chen Minren, IMSBU GM David Tsai and IABU Product Director Li Wenjian of IABG

(left to right) DGC’s IABU Inverter Product Director Shi Wenyang, IABU GM Chen Minren, IMSBU GM David Tsai and IABU Product Director Li Wenjian of IABG