The application of artificial intelligence (AI) has become a mainstream trend across the globe. According to a research report published by Market and Markets, the size of the global manufacturing industry is expected to grow at 21.5% annually over the next five years following a gradual increase in the adoption of AI-based computer vision technology across this industry. This projection suggests that companies are actively incorporating AI technology into their production processes in order to increase efficiency and enhance competitiveness.

AI-based computer vision refers to the ability to understand and process images or video using AI, encompassing various functions such as object detection, recognition, classification, and tracking. The more advanced technology in AI-based computer vision is deep learning. Unlike traditional machine learning applications that provide efficient and accurate judgments within an established framework, deep learning makes judgments by means of deeper algorithms in order to cope with more flexible problems. Hence, deep learning is able to complete tasks that could not be accomplished by machine learning in the past. For instance, in the industrial sector, deep learning is able to identify the actions of production line personnel and check the completion of assembly.

During the production process in the manufacturing industry, manual operation is yet to be completely replaceable due to the high costs of building fully automated equipment and complex actions in the assembly process. Advanced AI-based computer vision technology can help overcome problems related to manual operation, such as improving first-pass yield in production lines, lowering rework rates, and even preventing recall or return of products and other situations that may affect a company’s reputation. Furthermore, AI-based computer vision can help factories enhance competitiveness by shortening new product introduction time, reducing operation monitoring mechanisms, and thus cutting labor costs.

In an effort to address the problems faced by companies in manual production lines, the Delta Research Center (DRC) has not only developed an AI software program for advanced computer vision, which has passed a field trial, but also funded and witnessed by Corporate to launch the Advanced Industrial Computer Vision Solution Business Division (AICBD), a new business division that it is also sponsored by the Industrial Automation Business Group (IABG) in May this year, with a view to providing logic of action-based recognition technology to improve product assembly yield and increase first-pass yield, as well as assembly process monitoring technology to ensure the quality of finished products and achieve the required reliability.

Increase assembly first-pass yield to improve production efficiency

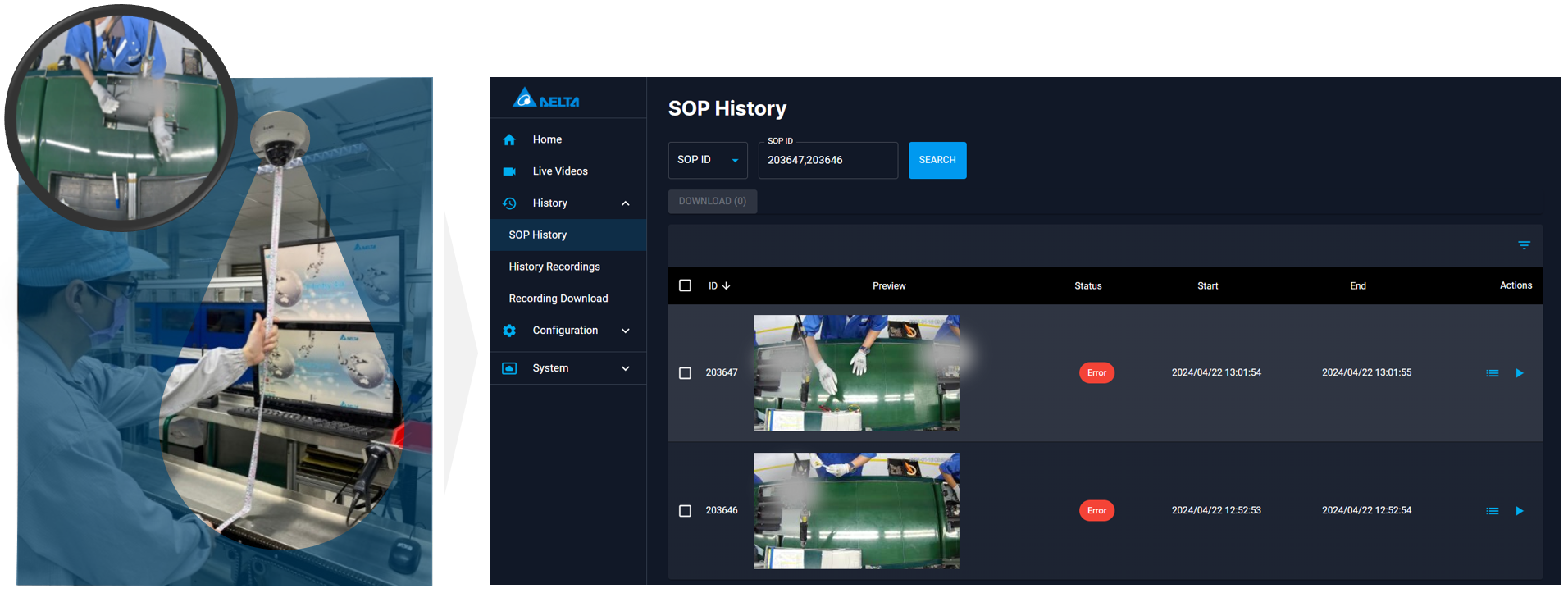

The manual assembly quality solution developed by Delta can improve assembly first-pass yield in production lines. With this solution, image data at workstations are collected via an AI-based management platform for the purpose of making inferences and performing analysis, which can accurately monitor assembly compliance in each step on the production line, and thus reduce factors that cause poor quality such as wrong materials, missing parts, and reverse direction. For complex assembly processes, this solution can lower production costs and shorten working hours if heavy workload can be reduced, thereby increasing production capacity.

The manual assembly quality solution developed by Delta can improve assembly first-pass yield in production lines.

The manual assembly quality solution developed by Delta can improve assembly first-pass yield in production lines.

Enhance product quality to increase product competitiveness

Delta’s advanced industrial computer vision solution can help companies enhance competitiveness as it can check the accuracy of operations if used in the monitoring of critical steps. For instance, during the manual attachment of heat sinks, even though heat sinks usually do not affect the electrical test results, if the attachment process is not carried out properly, it could potentially cause the product to malfunction due to overheating after shipment. In addition, an increasing number of companies are asking for solutions when seeking OEM partners, e,g., for automotive products, to ensure product stability during production line inspections. Therefore, the adoption of AI-based computer vision in factories is gradually becoming a plus point in the selection process. What we can anticipate is, as this technology matures and becomes ubiquitous, the adoption of AI-based computer vision will become a necessary equipment for production lines.

The rapid development of AI-based computer vision technology will bring great opportunities and challenges to the manufacturing industry. Companies that are able to keep abreast of technology development trends and take effective strategic measures to cope with new challenges will have a better chance to stand out from the fierce market competition and gain a lasting competitive advantage. It is believed that AI-based computer vision technology will become one of the indispensable key technologies in the manufacturing industry in the foreseeable future. It is believed that AI-based computer vision technology will become one of the indispensable key technologies in the manufacturing industry in the foreseeable future.

It is believed that AI-based computer vision technology will become one of the indispensable key technologies in the manufacturing industry in the foreseeable future.