Prefabricated data centers facilitate expansion of over 70,000 km of fiber optic networks in Europe

Among all prefabricated data center solutions, containerized data centers stand out as one of the typical representatives. Eurofiber, the leading B2B technology specialist, with over 600 employees is headquartered in the Netherlands and offers its customers ultra-modern infrastructure to drive forward digitalization in business and society. The company runs a fiber network that is currently more than 70,500 kilometers long and growing by 50 kilometers every week. To ensure that this mighty pace of expansion of its network does not come at the expense of connection speeds, Eurofiber uses inline amplifiers (ILAs). These are placed roughly every 75 kilometers throughout the network and amplify the signal on the fiber. Among the technical solutions Eurofiber uses for its ILAs are Xubus Nodes from Delta.

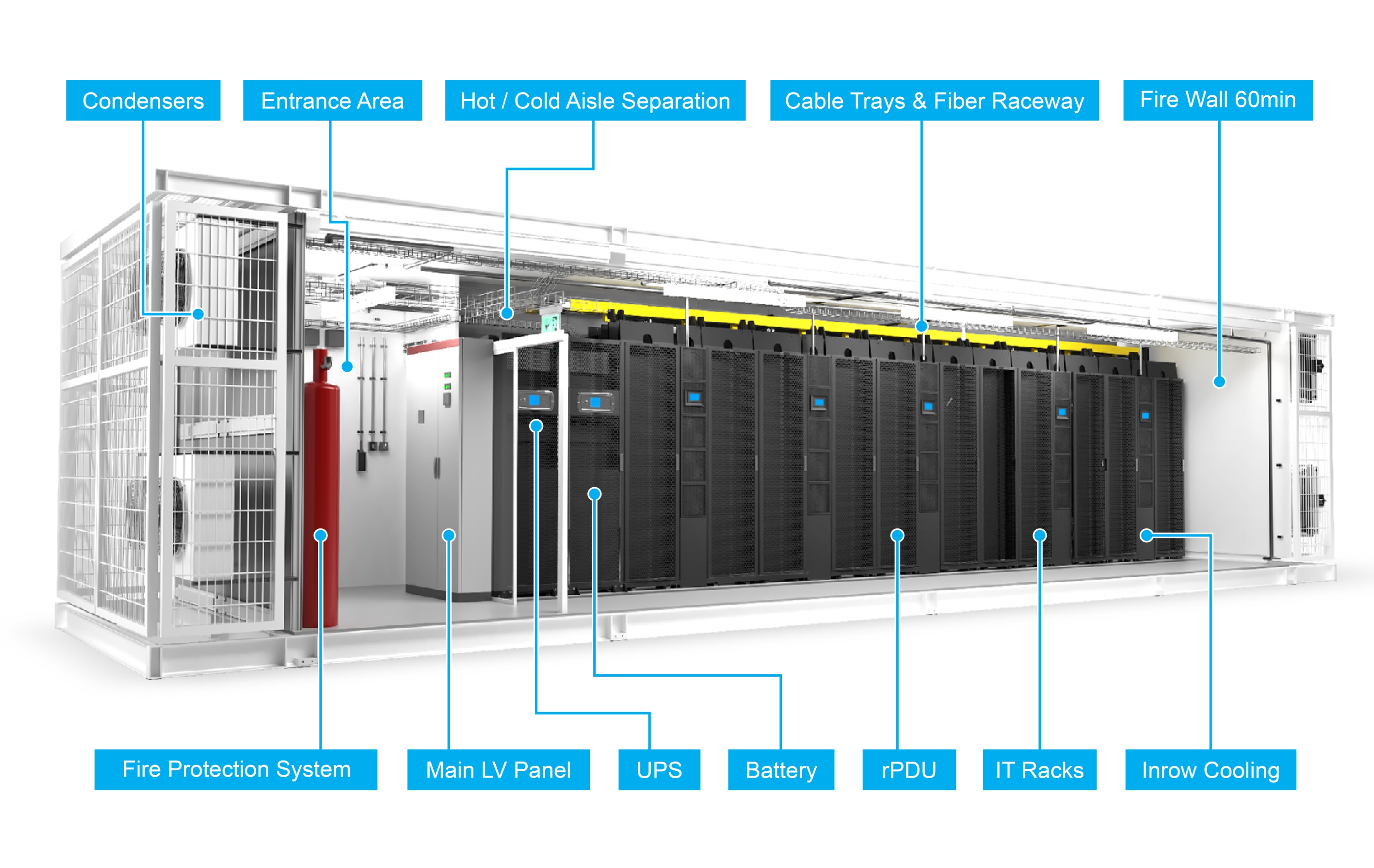

The Xubus Nodes come in five different configurations based on the IT workload. These turnkey, modular data centers are characterized by high performance and, above all, mobility. They are housed in various sizes of standardized containers, allowing them to be quickly and easily deployed to locations that do not yet have fully developed infrastructure but nonetheless require computing power. Eurofiber had its first, very positive, experience of using two Delta Xubus Nodes for a project back in mid-2022. To further expands its operations, the company required additional ILAs. However, the fiber network specialist did not want to use standardized Xubus Nodes. Instead, it asked Delta to develop a custom design focused on the lowest possible operating costs. Mr. Ines Jentink, Team Lead site of Eurofiber, said, “We selected Delta because of their experience and the reliability of the project plus the support and their oversight of the entire project. And because they are a manufacturer of highly efficient and reliable products.”

Delta team redesigned the system to meet Eurofiber's requirements.

Delta team redesigned the system to meet Eurofiber's requirements.

Customized solutions for achieving higher cost efficiency for customer

Within a short time window, the Delta team redesigned the system, making numerous design modifications, ranging from the UPS and cooling to illumination and the number of racks, not to mention the cabling system. The team’s redesign was precisely in line with the customer’s requirements, without compromising stability or reliability and they began procuring the necessary components. To permanently reduce operating costs, the newly custom-configured Xubus Nodes feature a number of differences compared with the off-the-shelf models. Cutting the power requirements down to size, the new ILAs use Delta DPH UPS modules in a N+4 configuration with a nominal rating of 30 kW, replacing the original two 75 kW UPS modules. The number of IT racks was also slashed in line with the customer’s requirements, from 13 to 4. In addition, Delta swapped out its standard in-row cooling system for an energy efficient R32-based ceiling cooling system to minimize the power consumption. Fire protection has also been adapted according to Eurofiber’s requests. Since there is no staff working on site, in addition to a standard fire alarm, a camera-based surveillance system has been integrated into the fire suppression system for remote monitoring.

Delta's prefabricated data center solutions, Xubus Node, can be housed in various sizes of standardized containers.

The full offer was complemented by a software solution to monitor all Delta-based ILAs in the field. Delta’s DCIM (Data Center Information Management) system allows customers to keep an eye on individual modules in their mobile data centers and monitor their real-time status remotely via cameras, including an analysis of power consumption. The status reports can be adjusted to reflect the customer’s individual needs and are displayed in a clear layout on a dashboard. “Modifying the Xubus Nodes so they are tailored to the customer’s requirements has been a challenging task, which has given us a great deal of valuable experience,” says Mandy Ho, DCSBU, sales manager at Delta. “We are already looking forward to future projects in which we can use this new knowledge to good effect.”

Click to watch the video for more details on Eurofiber’s case study. Delta's project experience and reliability convinced clients to collaborate with the team again.

Delta's project experience and reliability convinced clients to collaborate with the team again.

Prefabricated PTU solutions enhance efficiency in Australian mega data centers

Delta offers data center solutions of varying scales for different application scenarios. Recently, it successfully deployed prefabricated PTU (Power Train Unit) solutions for a megawatt-scale data center in Australia.

Unlike Eurofiber’s prefabricated data centers, the PTU solution is a prefabricated contained power sub-system. This type of prefabricated solution does not accommodate all data center infrastructure but is designed as a contained sub-system of the data center. It is typically used in large-scale data centers and offers the advantages of rapid deployment, scalability, high reliability, and high efficiency. Moreover, as the solution is completely independent of the data center, it allows customers to have more space for servers and other IT equipment.

Delta’s PTU (Power Train Unit) solutions for this site are rated to 1425kW utilizing the modular DPH UPS with UL9540A tested Delta Lithium-Ion batteries, water-cooled DX cooling, fire detection (VESDA) and gas fire suppression (NOVEC), and a fully customizable monitoring and management system using Delta’s Energy Management System (EMS) software platform. This advanced turnkey solution allows for rapid deployment to the site. For this project in Australia, Delta deployed 12 PTUs for the customer’s datacenter in 16 weeks in comparison to the 30-40 weeks typically required for a traditional power solution of the same scale. Moreover, providing a factory-tested solution saved considerable time and costs during the on-site testing and commissioning phase. Delta used high-power density products to provide a large-capacity power system based on minimal floor area.

Delta used high-power density products to provide a large-capacity power system based on minimal floor area.

Mr. Farhad Azizian, Delta Australia engineering manager, said, "Not only was this a major project, but it was also a real breakthrough for Delta as it is the first of its kind to be delivered to this site halfway through its expansion. Leveraging Delta’s high power density products, enabled us to deliver power solutions with substantial capacity in a minimal footprint to fit in site-limited space. To enhance the overall system efficiency, we incorporated a high-efficiency Delta UPS, implemented an energy-saving cooling solution using elevated water temperature, and optimized the supply-to-load delivery path to reduce losses. This resulted in a more sustainable solution in addition to saving energy and reducing client OPEX. This was made possible with close collaboration between our experienced engineering team, the client, and seamless coordination with the site contractor team.”

As demand for data centers explodes, in addition to the time and cost savings that can be achieved with prefabricated data center solutions, Delta’s trusted integration capabilities will continue to strengthen the competitiveness of its professional services for customers in various fields.